March 25, 2010 feature

Conical nanocarbon structures could lead to flexible, transparent field emission displays

(PhysOrg.com) -- During the past several years, researchers have used carbon nanotubes and nanofibers to fabricate a variety of transparent, flexible devices, such as OLEDs, transistors, and solar cells. But the development of transparent and flexible field electron emitters made of these nanomaterials still remains a challenge. In a new study, a team of researchers from Japan and Malaysia has shown that the key to the challenge may lie in the unique geometry of conical nanocarbon structures (CNCSs).

In their study, Pradip Ghosh of the Nagoya Institute of Technology and his coauthors have demonstrated how to fabricate CNCSs on a transparent, flexible substrate at room temperature. The resulting CNCS-based electron emitter could then be used as a field electron emission (FEE) source for transparent, flexible field emission displays (FEDs). FEDs are a new kind of flat panel display that have several advantages, such as high contrast and lower power consumption than liquid crystal displays (LCDs).

However, making FEDs transparent is very difficult since field electron emission requires a very high electric field and operation voltage. In order to achieve this high voltage, researchers usually use surfaces with a rugged sharp tip structure since the electric field is enhanced around the tip regions, enabling the operation voltage to be dramatically reduced. For this reason, as coauthor Masaki Tanemura from the Nagoya Institute of Technology explained, rugged surface structure is usually necessary for practical field electron emission sources, but so far ruggedness has not allowed for transparency.

“Imagine sand-blasted glasses,” Tanemura told PhysOrg.com. “Glasses are transparent, but sand-blasted glasses are not due to the light scattering by the rugged surface structure. Similar to this example, transparency has not been possible for FEE sources.”

By fabricating CNCSs that are smaller than the wavelength of visible light, the researchers found that they could overcome this challenge to produce fully transparent and flexible field electron emitters.

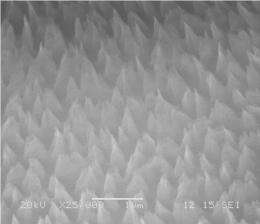

“CNCSs have given transparency and flexibility to FEE sources for the first time,” Tanemura said. “To get CNCS-based transparent materials, it is highly desirable to control the diameter and length of the CNCSs. We have successfully controlled the diameter and length of the CNCSs below the wavelength of visible light at room temperature using an ion irradiation method. A careful scanning electron microscopy (SEM) inspection revealed that the diameter and length of most of the CNCSs were lower than the wavelength of the visible light. Thus this unique structure of the CNCSs was very useful to fabricate a CNCS-based transparent and flexible field electron emitter.”

In their experiments, the scientists bombarded a nafion substrate with argon ions for 30 seconds at room temperature. The irradiation produced uniformly distributed CNCSs over the entire nafion surface. The scientists measured that individual CNCSs had a base diameter of about 200 nanometers and a length/height of a few hundred nanometers, which is smaller than the wavelength of visible light. Overall, the material’s emission characteristics (its turn-on and threshold fields) were comparable to previous opaque electron emitters.

As the researchers explain, the new method of using CNCSs for constructing transparent and flexible field electron emitters has several advantages. The method is simple in that it can be performed at room temperature, doesn’t require a catalyst, and doesn’t risk damaging the substrate. The scientists attribute these advantages to the unique conical geometry of the CNCSs.

As a next step, the scientists plan to fabricate a transparent, flexible phosphor material, which is necessary for observing visible light emission and for the future construction of complete FEDs. The researchers predict that the technique could lead to transparent, flexible FEDs that are lightweight and inexpensive.

“FED is a kind of flat panel display,” Tanemura explained. “Compared with other types of flat panel displays such as LCDs and electroluminescence displays, FED is advantageous in its brightness and size (a huge size is possible).”

He added that transparent, flexible FEDs have great potential for applications including so-called head-up displays and highly intelligent information displays used in the coming ubiquitous world, when computers become thoroughly integrated into our everyday activities.

“For example, head-up displays will be used on a curved front glass of vehicles (airplanes, trains, cars, and so on), full-face helmets, spectacles, and so on,” he said. “Usually it is transparent, but various kinds of information, such as maps, customer information, alarms, and security, will be displayed on demand. In the ubiquitous world, displays should be foldable (rollable) and light for mobility. You can enjoy TV, movies, games, communication, and obtain various kinds of information using an unfolded wide screen. Transparent and flexible FEDs make it realistic!”

More information: Pradip Ghosh, M. Zamri Yusop, Syunsaku Satoh, Munisamy Subramanian, Akari Hayashi, Yasuhiko Hayashi, and Masaki Tanemura. “Transparent and Flexible Field Electron Emitters Based on the Conical Nanocarbon Structures.” J. Am. Chem. Soc. Doi:10.1021/ja909346e

Copyright 2010 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.