March 17, 2010 feature

Vehicle shock absorber recovers energy from bumps in the road

(PhysOrg.com) -- In the past decade, regenerative braking systems have become increasingly popular, recovering energy that would otherwise be lost through braking. However, another energy recovery mechanism that is still in the research stages is regenerative suspension systems. This technology has the ability to continuously recover a vehicle's vibrational energy dissipation that occurs due to road irregularities, vehicle acceleration, and braking, and use the energy to reduce fuel consumption.

In a recent study, Professor Lei Zuo, Brian Scully, Jurgen Shestani, and Yu Zhou, all mechanical engineers from the State University of New York at Stony Brook, have designed and tested a retrofit regenerative shock absorber that recovers a vehicle's vibrational energy. The researchers built a 1:2 scale prototype of the regenerative shock absorber, and demonstrated its ability to harvest 2-8 watts of power during typical driving conditions at a speed of about 45 mph. They predict that a full-scale system on a four-wheel car should be able to recover up to 256 watts under these driving conditions.

“For typical driving conditions, we are predicting the ability to harvest approximately 64 watts per wheel, for a total of approximately 256 watts,” Zuo told PhysOrg.com. “This value increases considerably when the system is used on irregular roads.”

The purpose of the shock absorber in a vehicle's suspension system is to reduce the vehicle’s vibration by dissipating the vibrational energy. About 10 years ago, researchers began looking into recovering the vibrational energy using various magnetic devices. In general, these systems work by first absorbing the kinetic energy of suspension vibration between the wheel and a sprung mass, and then converting that energy into useful electric power.

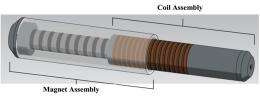

Zuo and his team’s shock absorber consists of two tube-like components: a smaller magnetic tube slides inside a larger, hollow coil tube. The coil component is made of copper coils wound around a plastic delrin tube, while the magnetic component is made of ring-shaped magnets separated by ring-shaped magnetically permeable spacers. The magnets are aligned with like-poles facing each other to produce a radially emitted magnetic flux. The magnetic tube is also surrounded by a high magnetically permeable material in order to further “pull” the magnetic flux outward. As Zuo explained, having a high magnetic flux is key to the design.

“The power we regenerate is proportional to the square of the magnetic flux across the coils,” he said. “Therefore, if we increase the flux by two times, the peak power output will increase by four times.”

When placed in the vehicle suspension, vibrations in the suspension cause the coil tube to move relative to the magnetic tube. As the copper coils move inside this magnetic field, a voltage is generated. The electricity can then be used to recharge the vehicle’s battery.

By recovering the vehicle’s vibrational energy and using it to drive the vehicle, the researchers hope that regenerative suspension system technology will be able to increase fuel efficiency and cut down on pollution. They note that, in the US, automobiles are a major source of several pollutants in the atmosphere, including 70% of the carbon monoxide, 45% of the nitrogen oxide, and 34% of the hydrocarbons. Further, fuel efficiency has lots of room for improvement: currently, only 10-16% of a vehicle’s fuel energy is used to drive the vehicle, i.e. to overcome the resistance from road friction and air drag. The rest is lost due to braking, vibrational energy dissipation, and other forms of loss.

“Regenerative braking harvests large amount of power in a very short time, in an intermittent manner,” Zuo said. “However, the regenerative shock absorbers can harvest the power in a continuous way. On the smooth highway road, the regenerative shock absorbers can improve the fuel efficiency by 2%, and on bumpy roads up to 10% increase can be expected.”

In the future, the researchers plan to increase the energy density and efficiency of the system by further increasing the magnetic field intensity and improving the harvesting electrical circuit. The New York State Energy Research and Development Authority (NYSERDA) will provide funding to support Zuo on this research and development work.

“We believe there is still room for improvement in the overall design of the regenerative system, and we are working on such improvement under funding support from NYSERDA,” Zuo said.

More information

Lei Zuo, Brian Scully, Jurgen Shestani, and Yu Zhou. “Design and characterization of an electromagnetic energy harvester for vehicles suspensions.” Smart Mater. Struct. 19 (2010) 045003 (10pp). Doi:10.1088/0964-1726/19/4/045003

Copyright 2010 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.