Scientists squeeze more out of metal-organic framework

(PhysOrg.com) -- Scientists at the U.S. Department of Energy's Argonne National Laboratory have discovered a new route to transform the structure of porous materials at industrially-accessible high pressures.

“Normally, these materials will spring back to their original structure after they have been compressed, almost like a spring, but above a certain pressure this material adopts a new structure,” Argonne scientist Karena Chapman said. “It is a related structure, but it is as if when we compressed the spring, it bounced back to a different shape.”

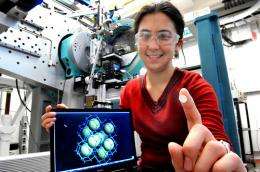

ZIF-8 is a commercially available metal-organic framework (MOF) with molecular-scale pores that can have valuable catalytic applications. Chapman, along with scientists Gregory Halder and Peter Chupas, used the Advanced Photon Source’s high-focused X-ray beams to observe the structure of the compound after it withstood varying degrees of pressure. The structural transition was found to occur at relatively modest pressures — pressures that can be achieved on the larger scales needed to test how the change in structure affects the compound's functional behavior.

Gas uptake measurements, carried out within the Materials Science Division, revealed that the material’s porosity was modified for the new structure. This could be used to optimize its performance for specific applications in areas such as hydrogen storage for fuel cells. This discovery shows that by exerting pressure on MOFs through the pelletization process, researchers can modify the compound's structure and storage property.

While this type of structural change has been seen in traditional porous materials (e.g., zeolites) at much higher pressures, the structural changes in the MOF material occur at lower pressures and consequently, this modification can be more readily scaled up to industrial levels.

The next step is for the scientists to examine the mechanism of the structural change and how this modification process can be most effectively exploited for molecular storage and separation applications.

More information: A paper about this discovery was recently published in the Journal of the American Chemical Society.

Provided by Argonne National Laboratory