October 27, 2009 feature

Scientists Make Ink Disappear, Make Paper Reusable

(PhysOrg.com) -- Despite ongoing efforts to save the trees, many offices print high volumes of paper documents on a daily basis. Although many companies encourage paper recycling, both disposing of and recycling paper have negative environmental impacts. What if there was a way to reuse printed paper by removing the ink and quickly transforming it back into clean, white paper?

That’s the idea from Thomas Counsell and Julian Allwood of the University of Cambridge, who have investigated print removal techniques in a recent study. Of course, as Counsell and Allwood note, the idea is not new. Since medieval times, monks have removed the print from parchment to allow it to be reused, and a handful of patents already exist on the concept, though the techniques used are unclear.

In 2006, Counsell and Allwood outlined a program of research into toner removal, and their most recent study, published in the Proceedings of the Royal Society A, demonstrates a promising toner removal method. They found that a combination of solvents can remove toner print from paper without harming the paper to make it reusable, although the resulting paper is not quite as white as new paper.

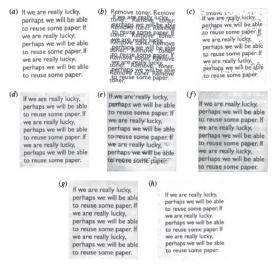

In experiments, the researchers used a single toner-paper combination: the toner came from an HP 4200 dtn black-and-white laser printer, while the paper was white, uncoated, wood-free 80 gm-2 Canon copy paper. Upon experimenting with several solvents and combinations, the researchers found that applying a mixture of 60% dimethylsulphoxide and 40% chloroform, followed by an application of ultrasound agitation to separate the pigment from the paper, could make the paper sufficiently reusable. As the researchers found, dimethylsulphoxide alone is poor at removing print but results in white paper, while chloroform is better at removing print but leaves a grey surface. Together, the solvents provide a paper that has a slightly off-white color and a slightly rougher surface than a new sheet of paper, but is still re-printable.

The scientists suggest that, in the future, a technique for removing print from paper might be carried out at a central recycling plant or in an office, such as by being integrated into a copy machine, printer, or recycling bin. But while solvents like chloroform would probably be acceptable to use at a plant, some solvents would probably not be considered safe for office use.

Before the researchers start considering implementing the technique, more work is needed, particularly in investigating the economic, safety, and environmental implications. For one thing, the researchers want to perform repeated tests on the paper over multiple cycles of reuse and over extended periods, in order to determine the lifespan of the paper. In addition, other paper types and printer types would likely work better with different solvents.

In addition to paper lifetime, there are sustainability issues to consider as well. For instance, in the experiments, at least 100 ml of solvent was required to clean a sheet of paper that had been covered with the standard 5% coverage of print that is quoted by printer manufacturers. At 10 sheets of paper cleaned per liter of solvent, the process raises questions about viability and the possibility of reusing the solvent, which would likely have further safety and economic issues. Despite these challenges, the basic principle of removing toner print from paper with solvents appears plausible, and may have benefits if investigated further.

More information: Thomas A. M. Counsell and Julian M. Allwood. “Using solvents to remove a toner print so that office paper might be reused.” Proceedings of the Royal Society A. doi:10/1098/rspa.2009.0144

Copyright 2009 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.