May 19, 2009 feature

'Writing' Patterns on Carbon Nanotubes With Polymer Chains

(PhysOrg.com) -- Carbon nanotubes are at the center of the nanoelectronics research movement, with scientists making great progress toward getting nanotube-based electronic devices into the hands of consumers. But one area of carbon nanotube research where there has been considerably less success is creating repeating, regular patterns onto individual nanotubes, a task necessary for a key goal of nanoelectronics: patterning transistors directly onto nanotube surfaces.

Now, as reported in a recent edition of Nature Nanotechnology, a research group has successfully used polymers to create well defined patterns onto single-walled carbon nanotubes.

“Very few reports have address periodic patterning on nanotubes, and those studies that have been conducted resulted in patterns that were poorly repeating rather than nicely periodic and uniform,” said the study's corresponding researcher, Christopher Li of Drexel University, to PhysOrg.com. “The success of our work appears to be in the polymer material we used.”

The group chose a block copolymer, a polymer chain formed by two (or more, in some cases) short polymer chains. In this case the two components are polyethylene (PE) and polyethylene oxide (PEO).

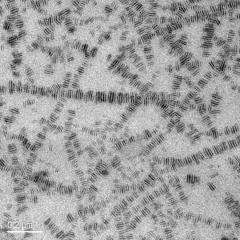

Li and colleagues at Drexel deposited a single-walled carbon nanotube solution onto a pre-fabricated carbon-coated grid. The nanotubes lined up on the grid surface and the group decorated the nanotubes with a solution containing the copolymer. The result is a copolymer/nanotube hybrid, which the group analyzed using a transmission electron microscope.

Even with the powerful microscope, the nanotubes were not visible under the copolymers, which formed worm-like structures with alternating dark and bright stripes (corresponding to the PEO and PE blocks, respectively). But the consistent spatial orientation of the stripes, and the size of the “worms,” averaging 50 nanometers wide and one micrometer long, indicate that the polymer chains forming the stripes had aligned with the long axes of the nanotubes; the stripes, then, cut across the nanotubes perpendicularly.

The researchers used copolymer solutions of varying concentrations and found that the stronger the solution, the more stripes formed on each nanotube. The process causing this to occur, they propose, begins when the copolymer molecules randomly adsorb onto a nanotube surface. These molecule clusters nucleate the growth of crystals and, with increasing concentration, more crystals appear, growing into larger patches.

At a critical concentration the patches connect and clear stripes begin to form. And when the concentration is too high, there are so many crystals forming on the nanotubes that they don't have time to align properly.

The period of the stripe pattern - that is, the distance between alternating stripes - is about 12 nanometers. This regularity is a key step toward fabricating multiple transistors on individual nanotubes.

Additionally, the group was able to attach gold nanoparticles to the copolymer/nanotube hybrid structures in fixed locations, adding another functional element to the pattern. This shows that it is possible to pattern other structures onto the nanotubes, a route toward tailoring them specific tasks in nanoelectronics.

More information: Bing Li, Lingyu Li, Bingbing Wang and Christopher Y. Li Nature Nanotechnology advance online publication 26 April 2009, DOI: 10.1038/nnano.2009.91

Copyright 2009 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.