'Self-healing' polymer may facilitate recycling of hard-to-dispose plastic

(PhysOrg.com) -- Researchers in The Netherlands are reporting development of a new plastic with potential for use in the first easy-to-recycle computer circuit boards, electrical insulation, and other electronics products that now wind up on society’s growing heaps of electronic waste. Their study appears in ACS’ Macromolecules.

Antonius Broekhuis and colleagues note in the new study that so-called thermoset plastics are widely used in consumer electronics due to their hardness and heat resistance.

These plastics, however, contain additives and reinforcement materials that make them almost impossible to recycle. So-called thermoplastics, in contrast, are softer and can be remelted easily. As a result, thermoset plastics often end up in landfills or incinerators, where they can contribute to pollution. Scientists have long-sought a simple, inexpensive process to make these plastics recyclable, but they have been largely unsuccessful until now.

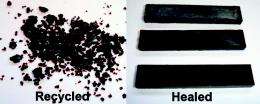

Broekhuis and colleagues describe development of a new type of thermosetting plastic that can be melted and remolded without losing its original heat-resistance and strength. The scientists showed in laboratory tests that they could melt granules of what they term a “self-healing” polymer and reform them into uniform, rigid plastic bars. They also showed that the plastic could be remolded multiple times, setting the stage for a new generation of recyclable plastics.

More information: Macromolecules, “Thermally Self-Healing Polymeric Materials: The Next Step to Recycling Thermoset Polymers?”

Provided by American Chemical Society (news : web)