Super Sensitive Gas Detector Goes Down the Nanotubes

When cells are under stress, they blow off steam by releasing minute amounts of nitrogen oxides and other toxic gases. In a recent paper,* researchers at the National Institute of Standards and Technology described a new method for creating gas detectors so sensitive that some day they may be able to register these tiny emissions from a single cell, providing a new way to determine if drugs or nanoparticles harm cells or to study how cells communicate with one another. Based on metal oxide nanotubes, the new sensors are a hundred to 1,000 times more sensitive than current devices based on thin films and are able to act as multiple sensors simultaneously.

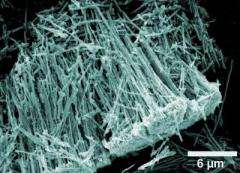

Gas sensors often operate by detecting the subtle changes that deposited gas molecules make in the way electricity moves through a surface layer. Thus, the more surface available, the more sensitive the sensor will be. Scientists are interested in developing gas sensors based on nanotubes because, having walls that are only a few nanometers thick, they are almost all surface.

Although nanotubes have proven to be well suited for gas sensing applications, fabricating the devices themselves is a difficult, imprecise and time-consuming process, according to Kurt Benkstein, an author of the paper. Older methods include randomly scattering free nanotubes on a surface with preformed electrical contacts (the hope being that a least a few of the nanotubes would tumble into place) or laying contacts over the top of the nanotubes after they had been dispersed, among others. These methods, though they can result in functional devices, preclude researchers from knowing where exactly the reactions are happening on the substrate. This makes it impossible to do multiple simultaneous tests. Also, these sensors are not as sensitive as they could be because there is no way to ensure that the gas is reacting with the interior of the tube.

To address these problems, the NIST group built upon another design using a sheet of aluminum oxide about the thickness of a human hair and perforated with millions of holes about 200 nanometers wide. With the nanosized pores serving as a mold, the researchers dipped the aluminum oxide sheet in a solution of tungsten ions, coating the interior of the pores and casting the nanotubes in place. After the nanotubes were formed, the team deposited thin layers of gold on the top and bottom of the aluminum oxide membrane to act as electrical contacts. View schematic of the nanotube sensor at patapsco.nist.gov/ImageGallery … ails.cfm?imageid=620.

The sensor’s high sensitivity derives from its design, which ensures that any sensor response is the result of the gas interacting with the interior of the nanotube. The researchers also note that this same technique can easily be adapted to form nanotubes of other semiconductors and metal oxides so long as the ends of the nanotubes remain open.

Note:

* R. Artzi-Gerlitz, K. Benkstein, D. Lahr, J. Hertz, C. Montgomery, J. Bonevich, S. Semancik, M. Tarlov. Fabrication and gas sensing performance of parallel assemblies of metal oxide nanotubes supported by porous aluminum oxide membranes. Sensors and Actuators B: Chemical. Available online Nov. 11, 2008.

Source: National Institute of Standards and Technology