Breakthrough for carbon nanotube materials

(PhysOrg.com) -- In collaboration with scientists from the NanoTech Institute of the University of Texas at Dallas (UTD) – CSIRO has achieved a major breakthrough in the development of a commercially-viable manufacturing process for a range of materials made from carbon nanotubes.

Carbon nanotubes possess a number of qualities – high tensile strength, high flexibility, high electrical and thermal conductivity, and transparency – which have excited great interest in a number of manufacturing industries including the electronic, automotive, energy and clothing industries.

The flexible carbon nanotubes have been spun into ribbons that conduct electricity efficiently – and are five times stronger than steel.

Until now, the application of carbon nanotube technology has been severely limited due to the lack of a cost-efficient method of producing large sheets of carbon nanotube material.

However – as reported in today’s edition of the prestigious international scientific journal, Science – the UTD/CSIRO team recently demonstrated that synthetically made carbon nanotubes can be commercially manufactured into transparent sheets that are stronger than steel sheets of the same weight.

Carbon nanotube materials have a number of potential applications in, for example: organic light emitting displays, low-noise electronic sensors, artificial muscles, conducting appliqués and broad-band polarized light sources that can be switched in one ten-thousandth of a second.

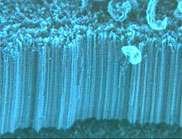

Starting from chemically grown, self-assembled structures in which nanotubes are aligned like trees in a forest, the sheets are produced at up to seven meters per minute. Unlike previous sheet fabrication methods – using dispersions of nanotubes in liquids – this dry-state process produces materials made from the ultra-long nanotubes required to optimise their unique set of properties.

“Rarely is a processing advance so elegantly simple that rapid commercialisation seems possible, and rarely does such an advance so quickly enable diverse application demonstrations”, says Dr Ray H. Baughman of the NanoTech Institute.

“Synergistic aspects of our nanotube sheet and twisted yarn fabrication technologies will likely help accelerate the commercialisation of both technologies, and UTD and CSIRO are working together with companies and government laboratories to bring both technologies to the marketplace.”

Provided by CSIRO