NIST helps heat pumps 'go with the flow' to boost output

Air-source heat pumps typically deliver 1 1/2 to three times more heating energy to a home than the electric energy they consume. This is possible because heat pumps move heat rather than convert it from a fuel (as combustion heating systems do). National Institute for Standards and Technology researchers are working to improve the performance of these energy superstars even further by providing engineers with computer-based tools for optimizing heat exchanger designs.

In a typical air-source heat pump, air flows over two refrigerant-filled heat exchangers (known as coils): one indoor and the other outdoor, both of which have metal fins to aid heat transfer. In the heating mode, liquid refrigerant within the outside coil extracts heat from the air and the refrigerant evaporates into a gas. The indoor coil releases heat from the refrigerant as it condenses back into a liquid. A valve near the compressor can change the direction of the refrigerant flow for cooling.

Performance of air-to-refrigerant heat exchangers can be reduced by uneven air flow distribution. However, performance degradation can be significantly avoided by design changes that increase refrigerant flow in areas that receive more air. To achieve this, one must ascertain the actual air distribution in a given system.

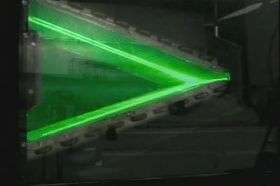

NIST researchers have developed a testing apparatus that uses a high-resolution camera to track—with laser-illuminated dust particles—the motion and distribution of air flow in finned-tube heat exchangers. Data from these highly accurate laboratory experiments are being compared with computer simulations of air flow performed with computational fluid dynamics (CFD) software. Once accurate CFD models are developed and validated, engineers could use them as the basis for design changes to coil assemblies and refrigerant circuitries to accommodate the existing air distribution.

The NIST program, partially sponsored by the Air-Conditioning and Refrigeration Technology Institute (ARTI) under a Cooperative Research and Development Agreement (CRADA), could increase finned-tube heat exchanger heating or cooling capacity by five percent, resulting in improved heat pump efficiency. Additionally, such improvements could allow manufacturers to reduce the heat exchanger size, thereby reducing material cost and the amount of refrigerant needed. The NIST study results on home air-source heat pumps will be issued in 2009 and are also expected to be applicable to large heat exchangers used in commercial buildings and refrigeration systems.

For further information, go to www.bfrl.nist.gov/863/HVAC

Source: National Institute of Standards and Technology