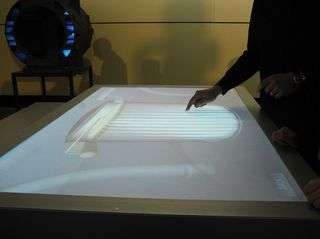

Virtual factory on the tabletop

Many industrial processes involve reactions in places that are difficult to see directly. A novel tabletop touch screen allows hidden sequences of events to be observed in progress. It can be operated intuitively using a combination of fingers and recognizes swiping movements.

A crowd of people is gathered around a large table with an illuminated surface, on which images of a journey through pipes and machines in a factory are being displayed. Users can select individual components by touching the corresponding image with a finger. The objects can be rotated and observed by swiping a finger over them – and the same method can be used to watch a process in slow motion.

By drawing apart their two index fingers on the table surface, users can enlarge the image and zoom in on a detail, such as a bay wheel scooping up hundreds of thousands of plastic granules. The Multi-Touch Table provides a tangible virtual replication of processes that normally take place hidden inside networks of pipes: How does the process work? What are its advantages?

The large, industrial-scale display table was developed by researchers at the Fraunhofer Institute for Computer Graphics Research IGD in Darmstadt. “The table is already being used by the Coperion Group of companies,” relates IGD project manager Michael Zöllner. “It allows customers to observe the entire process chain of plastics manufacturing and processing. They can watch in real time as the granulate flows through the pipes and regulate the speed by swiping a finger over the image.” The researchers worked with colleagues at the Steinbeis Institute Design and Systems on the development of this application.

So how does the touch screen work? Infrared LEDs emit light into the Plexiglas® surface of the display at a horizontal angle. This light is internally totally reflected within the acrylic sheet, which allows none of the light to escape. A finger placed on the surface changes its reflective properties, enabling light to emerge. This light is captured by an infrared camera installed beneath the table. Although the system is based on well-known principles, various challenges still had to be overcome.

“The surface of acrylic sheets is too smooth to resolve finger movements. Our solution was to apply a special coating,” says Zöllner. Another problematic aspect was how to project the images. “To obtain a large, bright, undistorted image, the optical path has to be relatively long – something that is difficult to achieve within the confines of the table below the display. We had to affect the optical path itself, by using mirrors to keep it short,” the research scientist explains. As for the user interface, the researchers made sure that it could be used easily and intuitively. After all, nobody wants to have to follow complicated technical instructions when meeting with customers or visiting a museum.

Source: Fraunhofer-Gesellschaft