September 4, 2015 report

Holographic lens printing method could allow printing of telescope lenses in space

(Phys.org)—Researchers have developed a method for printing optical holographic lenses that could greatly simplify their fabrication. Because the method can be performed quickly and easily, it could potentially be used by astronauts to print lenses while in space for holographic lens telescopes.

The researchers, led by Dr. Haider Butt at the University of Birmingham in the UK, along with coauthors from there and the Harvard Medical School and Wellman Center for Photomedicine at Massachusetts General Hospital in the US, have published a paper on the new holographic lens printing method in a recent issue of ACS Nano.

"Using the novel technique of holographic laser ablation, which we previously used for printing holograms, we have demonstrated the printing of optical lenses made of a variety of materials," Butt told Phys.org. "A complete lens can be fabricated with a single nanosecond laser pulse. Hence the method is fast, flexible, and inexpensive."

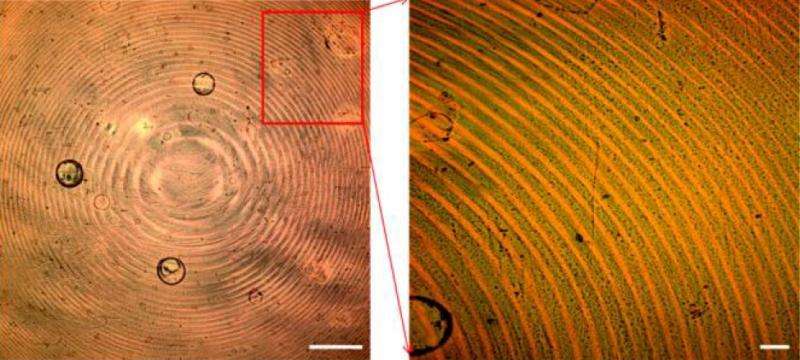

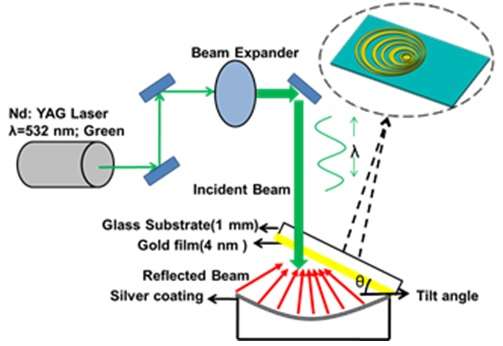

While current holographic lens fabrication methods are often expensive, time-consuming, and labor-intensive, the new printing method can produce a lens in just a few seconds using only a single step. The method uses a nanosecond laser pulse to create interference patterns on a transparent substrate coated with light-absorbing materials. The laser is reflected off a concave mirror back onto itself, so that interference occurs between two laser beams traveling in opposite directions. The resulting interference pattern, consisting of circular fringes, is "printed" on a substrate between the two beams, storing the optical information as a holographic lens. The resulting flat, ultra-thin lenses consist of hundreds of nanoscale circular zones that contribute to focusing light.

Using this new method, the researchers demonstrated that they could achieve mass production within a few minutes. The method should also work with a wide variety of materials on substrates that are semitransparent, with geometries that are flat, curved, or of other arbitrary form.

Besides having niche applications like printing telescope lenses in space, the new printing method could also be used for security, data storage, and biosensors. Due to the flexibility of the fabrication method, lenses can be printed on certain materials that are not compatible with conventional fabrication techniques. In the future, the scientists plan to use the method to print lenses on thin films of semiconductors, with applications in applied optics and infrared imaging.

More information: Qiancheng Zhao, et al. "Printable Nanophotonic Devices via Holographic Laser Ablation." ACS Nano. DOI: 10.1021/acsnano.5b03165

Group webpage: HB-Nanophotonic Group at the University of Birmingham

Journal information: ACS Nano

© 2015 Phys.org