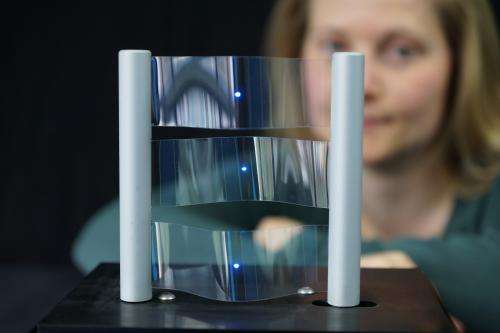

Developers present conductive coatings for flexible touchscreens

As one of the few German institutions there and working in cooperation with the VDI Association of German Engineers, INM will be presenting these and further developments at Stand 301 in the German Area.

There, the INM will be presenting new nanoparticle inks, which can be printed directly onto thin plastic films by simple processes. Gravure printing is used to form transparent conductor tracks and structures, which still remain electrically conductive even when the films are deformed.

For the nanoparticle inks, the researchers are using what are known as TCOs, or transparent conducting oxides. "We use the TCOs to produce nanoparticles with special properties", says Peter William de Oliveira, Head of the Optical Materials Program Division, "the TCO ink is then created by adding a solvent and a special binder to these TCO particles". The binder performs several tasks here: it not only makes the TCO nanoparticles adhere well on the film; it also increases the flexibility of the TCO coating: in this way, the conductivity is maintained even when the films are bent. The ink can then be applied to the film directly by gravure printing using a printing plate. After curing under UV light at 150°C, the coating is ready.

The transparent electronic inks allow conductor tracks to be produced unproblematically even on a large-scale by means of the classic reel-to-reel process. Initial trials at INM have been promising. The researchers all agree that the use of structured rollers will in the future allow even large, structured conductive surfaces to be printed with a high throughput at low cost. Conductive coatings with TCOs are usually applied by means of high vacuum techniques. The method known as sputtering, however, is very expensive.

Provided by INM - Leibniz-Institut für Neue Materialien