New composite protects from corrosion at high mechanical stress

Material researchers at the INM – Leibniz Institute for New Materials will be presenting a composite material which prevents metal corrosion in an environmentally friendly way, even under extreme conditions. It can be used wherever metals are exposed to severe weather conditions, aggressive gases, media containing salt, heavy wear or high pressures.

The INM from Saarbruecken will be one of the few German research institutions at the TechConnect World trade fair on 16 and 17 June in Washington DC, USA, where it will be presenting this and other results. Working in cooperation with the VDI Association of German Engineers it will be showcasing its latest developments at Stand 301 in the German Area.

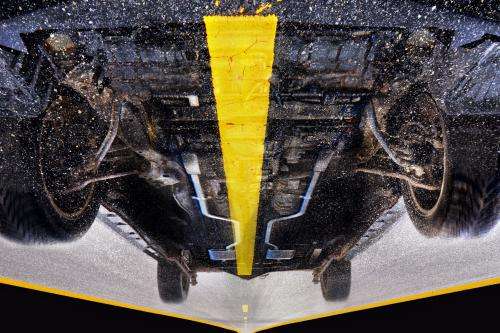

"This patented composite exhibits its action by spray application", explains Carsten Becker-Willinger, Head of the Nanomers Program Division. "The key is the structuring of this layer - the protective particles arrange themselves like roof tiles. As in a wall, several layers of particles are placed on top of each other in an offset arrangement; the result is a self-organized, highly structured barrier", says the chemical nanotechnology expert. The protective layer is just a few micrometers thick and prevents penetration by gases and electrolytes. It provides protection against corrosion caused by aggressive aqueous solutions, including for example salt solutions such as salt spray on roads and seawater, or aqueous acids such as acid rain. The protective layer is an effective barrier, even against corrosive gases or under pressure.

After thermal curing, the composite adheres to the metal substrate, is abrasion-stable and impact-resistant. As a result, it can withstand high mechanical stress. The coating passes the falling ball test with a steel hemispherical ball weighing 1.5 kg from a height of one meter without chipping or breaking and exhibits only slight deformation, which means that the new material can be used even in the presence of sand or mineral dust without wear and tear.

The composite can be applied by spraying or other commonly used wet chemistry processes and cures at 150-200°C. It is suitable for steels, metal alloys and metals such as aluminum, magnesium and copper, and can be used to coat any shape of plates, pipes, gear wheels, tools or machine parts. The specially formulated mixture contains a solvent, a binder and nanoscale and platelet-like particles; it does not contain chromium VI or other heavy metals.

Provided by INM - Leibniz-Institut für Neue Materialien