April 10, 2013 weblog

PARC goes xerographic: Is that any way to make a computer?

(Phys.org) —Talk about taking chip assembly to the next level: That 3-D-printer is not only to make the personalized phone case but the phone. At least this idea has some potential with a recent report making the rounds this week, where the author of an article in The New York Times wrote about what scientists at Palo Alto Research Center (PARC) are up to.

They are building on a technique known as xerographic micro-assembly, possibly the future way of printing circuitry for electronics. The approach in the spotlight is based on laser printing, something about which Xerox knows more than a little. The machines they designed for their explorations is a laser printer like machine with the ability to precisely position large numbers of chiplets, tiny-sized chips, on a surface in the right place and in the right orientation. The chip designs are custom-assembled. The PARC researchers have been working on this with financing from the National Science Foundation and from the Defense Advanced Research Projects Agency (DARPA).

Future implications may be desktop manufacturing plants using chiplets to print circuitry for electronic devices. The system could be put to use toward building custom computers one at a time or as a system making a range of smart objects with computing as one of the object's features.

In a discussion of the technical challenges facing this initiative, ExtremeTech concluded nonetheless that if the PARC group can succeed in combining the assembly of electronic and mechanical components in new ways, then "we can look forward to some interesting products."

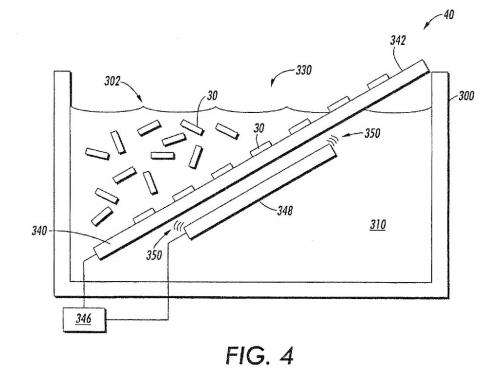

Back in 2004, PARC's Eugene Chow and Jeng Lu filed a patent for "Xerographic micro-assembler." They defined the ideas as both system and methodology. "The systems and methods involve manipulating charge-encoded micro-objects. The charge encoding identifies each micro-object and specifies its orientation for sorting. The micro-objects are sorted in a sorting unit so that they have defined positions and orientations. The sorting unit has the capability of electrostatically and magnetically manipulating the micro-objects based on their select charge encoding. The sorted micro-objects are provided to an image transfer unit. The image transfer unit is adapted to receive the sorted micro-objects, maintain them in their sorted order and orientation, and deliver them to a substrate. Maintaining the sorted order as the micro-objects are delivered to the substrate may be accomplished through the use of an electrostatic image, as is done in xerography. The substrate with the micro-objects is further processed to interconnect the micro-objects—through electrical wiring, for example—to form the final micro-assembly."

© 2013 Phys.org