December 2, 2011 weblog

Spandex manufacturer makes elastic electrical cable (w/ video)

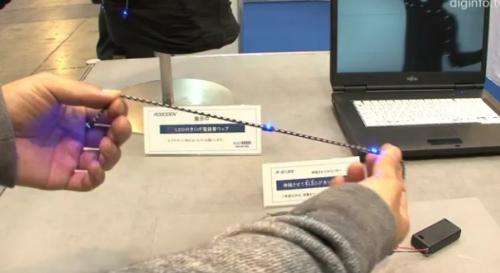

(PhysOrg.com) -- Japanese company Asahi Kasei Fibers, which manufactures spandex and other textiles, has applied its knowledge of stretchable materials to make stretchable elastic power and USB cables.

Researchers at Asahi Kasei originally designed the elastic cable material, called Roboden, for wiring the soft, flexible skin of humanoid robots. As the researchers explain, human skin can stretch by a factor of 1.5, the same as the new cable. As a result, the wiring can stretch with the robots’ movements, such as twisting and turning, without losing its ability to transfer power and data.

In the form of power and USB cords, the elastic cables could prove useful for minimizing cord clutter in homes and offices. The cable material is made of an outer elastic shell with spiraled internal wiring that unspirals when pulled.

Another application of the elastic cables could be wearable electronics - possibly for health-monitoring materials, wearable solar panels, and futuristic electronic clothing fashions.

More information: via: DigInfo News

© 2011 PhysOrg.com