Contact Through Silver Particles in Ink

Modern cars are full of sensors. The optimum quantity of air in the intake tract of a combustion engine is regulated by thermoelectric flow sensors, for instance. They measure which quantities of a gas or a liquid flow in a particular direction. Another application for sensors like these is in medicine, where they regulate tiny quantities of drugs.

These thermoelectric sensors depend for their correct function on the right contact: The measuring sensors, consisting of a silicon wafer and a membrane, are embedded in a printed circuit board. So that the necessary current can flow between the contacts of the sensor and the printed circuit board, a conductor path has to be created – experts speak of ‘contacting’.

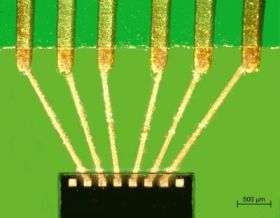

Researchers at the Fraunhofer Institute for Manufacturing Engineering and Applied Materials Research IFAM in Bremen (Germany) are working on a special technique: “Up to now, contacting was usually done with wire bonds – thin wires, that is,” explains IFAM project manager Christian Werner. “But wire bonds stick out, and thus impair the flow behavior of the gases and liquids. That can affect high-precision measurements.”

The researchers have therefore developed a new technique: INKtelligent printing®. What is different about this technique is that the researchers print the conductor paths instead of wiring them. This is basically a contactless aerosol printing method. The secret lies in the ink: “The suspension contains nano silver particles in a special solvent,” says Werner. “This enables us to print extremely thin-layered conductor paths.” Subsequent thermal treatment activates the electrical conductivity of the paths.

The researchers have tried and tested these conductor paths together with colleagues from the Institute for Microsensors, -actuators and -systems IMSAS in Bremen. Altogether, the engineers have solved one of the main problems of thermoelectric sensors. In contrast to wire bonds, which have an overall height of 1 to 1.5 millimeters, the printed conductor paths are a mere 2 to 3 micrometers high, or almost five hundred times thinner than wire bonds. This enables the sensors to make far more accurate measurements.

Source: Fraunhofer-Gesellschaft