Bones at the nanoscale

Scientists from Max Planck Institute (Germany) and the European Synchrotron Radiation Facility have just discovered the way deformation at the nanoscale takes place in a bone by studying it with the synchrotron X-rays. This study explains the enor-mous stability and deformability of bones. The hierarchical structure of bones makes them able to sustain large strains without breaking, de-spite being made of essentially rigid units at the molecular level. The re-sults are published this week in the PNAS online edition.

A bone is made up of two different elements: half of it is a stretchable fibrous protein called collagen and the other half a brittle mineral phase called apatite. These com-ponents make this biomineralized tissue highly strong and tough. at the same time, In order to understand how this construction is achieved and functions, scientists from the Max Planck Institute of Colloids and Interfaces in Potsdam (Germany) came to the ESRF. Using X-rays they were able to see for the first time the simultaneous re-arrangement of organic and inorganic components at a micro and nanoscale level under tensile stress.

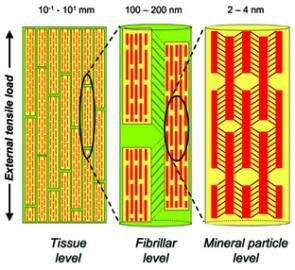

The scientists realised that when strain/pressure is applied to a bone, this is ab-sorbed by soft layers at successively lower length scales, and less than a fifth of the strain is actually noticed in the mineral phase. The soft structures form a single rigid unit at the next level and so on, enabling the tissue to sustain large strains. This is why the brittle apatite remains shielded from excessive loads and does not break.

The results also showed that the mineral crystallites are nonetheless very strong, ca-pable of carrying more than 2 – 3 times the fracture load of bulk apatite. Their small size preserves them from large cracks. This is the first experimental evidence for this effect in biomaterials – small particles resist failure better.

The experiments were carried out at the ESRF using an X-ray beam of 200 microns wide by 40 microns high. Scientists tracked the molecular and supramolecular rear-rangements in bone while they applied stress using the techniques of X-ray scatter-ing and diffraction in real time. The high brilliance of the X-ray source enabled the tracking of bone deformation in real time. Researchers could look at two length scales: on one side they observed the 100 nanometers sized fibres, and on the other, the crystallites embedded inside the fibre, which are not bigger than 2 to 4 nanome-ters. The critical sample preparation was developed by Max Planck researchers, which made it possible to isolate tissue in bone of about 100-200 microns of size.

These results provide new insight in the design principles which make healthy bone so fracture resistant. The research may contribute to medical as well as technological developments: "The outcome of this research may contribute to a future development of bio-inspired and new nanocomposite materials. On a medical level, it may help to understand how a molecular level change can make whole bones more prone to frac-ture in diseases like osteoporosis", explains Himadri Gupta, first author of the paper. Further ongoing research aims at telling us how these design principles differ in bones with different mechanical function and how they may be affected by age and disease.

Source: European Synchrotron Radiation Facility