August 25, 2006 feature

Nanoscience May Produce 'Perfect' Materials

Nanoscience may provide a way to engineer materials that are virtually defect-free – perfect, that is.

A scientist at North Carolina State University has discovered that the tiny grains comprising many bulk materials can potentially contain nearly zero structural imperfections when the grains are smaller than a certain critical size, typically a few to several nanometers.

Therefore, materials created with grains of the right size could be structurally flawless. Not only would these materials possess exceptional strength and durablity, but their optical, electrical, and magnetic properties could be vastly improved as well. The number of potential applications, such as smart sensors and ultra-efficient “solid-state” lighting, as well as entire industries impacted, such as automobiles and defense, is staggering.

“Nanostructured materials offer a unique opportunity to realize perfect materials with greatly improved properties,” said NCSU materials scientist Jagdish (Jay) Narayan, the study's sole researcher, to PhysOrg.com. “Copper, for example, can be made as strong as steel by reducing the grain/feature size so that defects cease to exist.”

In his paper describing the work, published in the August 7 online edition of the Journal of Applied Physics, Narayan discusses the many types of defects that can be present in a material and shows, via theoretical arguments and a couple of specific examples, how controlling grain size may be able to prevent them.

For example, one type of defect is a dislocation, an irregularity in the repetitive pattern of a crystalline material that compromises strength. It is nearly impossible to eliminate dislocations, Narayan says, but reducing the grain size can theoretically restrict the movement of a dislocation so that it can't propagate through the rest of the material. For copper, he calculates that this will occur at the critical grain size of about 7.5 nanometers (nm).

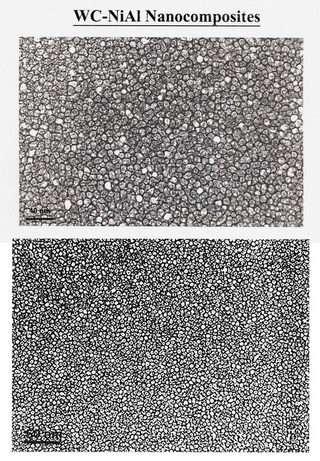

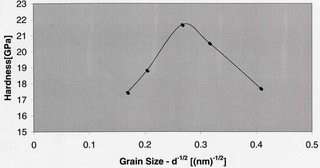

He provides a specific example of how grain size affects a material's properties, using a nanocomposite material made of two compounds, tungsten carbide (WC) and nickel aluminide (NiAl). The NiAl component acts as a hardening agent, bonding with atoms at the surface of WC nanoparticles. Because WC-NiAl grains are all about the same size, it is a good material for testing how grain size affects hardness. The results show the hardness of WC-NiAl increases as its grain size decreases, but only down to a critical grain size. Below that, the material begins to get softer.

But there are some challenges to overcome before a “perfect” material could truly be achieved. The problems lie at the interfaces between grains, where the surfaces of two grains meet. There, some defects may persist because it is difficult for scientists to control certain properties and grain-to-grain interactions, such as atomic structure, chemistry, and atomic bonding.

Just how difficult is determined by the ratio of surface atoms to inner-grain atoms. As grain size gets smaller, this ratio gets larger – there are more and more surface atoms relative to non-surface atoms. Through additional research, scientists may be able to make adjacent grains come together harmoniously and prevent defects between them.

Citation: Journal of Applied Physics, Volume 100, 0034039 (2006)

By Laura Mgrdichian, Copyright 2006 PhysOrg.com