This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

New strategy to obtain carbon nanotube fibers with higher dynamic strength

In a study published in Science on June 21, Prof. Jian Muqiang from Peking University and the Beijing Graphene Institute and others developed a strategy to fabricate carbon nanotube fibers with the dynamic strength up to 14 GPa.

Lightweight and high strength are perpetual pursuits for fiber materials. In response to the application requirements of fibers in high strain rate scenarios such as battlefield protection and space debris capture, it is of significant importance to develop fiber materials with ultra-high dynamic strength and high energy absorption capability.

Carbon nanotubes, with their excellent properties of being lightweight, strong, high modulus, highly electrical and thermally conductive, are considered one of the ideal building blocks for the next generation of high-performance fibers, promising to meet the needs of high strain rate applications.

However, due to issues related to fiber assembly structure, the tensile strength of carbon nanotube fibers remains less than 10 GPa, far below their ideal strength, indicating substantial room for improvement.

Researchers including Prof. Wu Xianqian from the Institute of Mechanics of the Chinese Academy of Sciences (CAS), Assoc. Prof. Gao Enlai from Wuhan University, Prof. Zhang Yongyi from the Suzhou Institute of Nano-Tech and Nano-Bionics of CAS, and others, therefore proposed an innovative multi-scale structural optimization strategy.

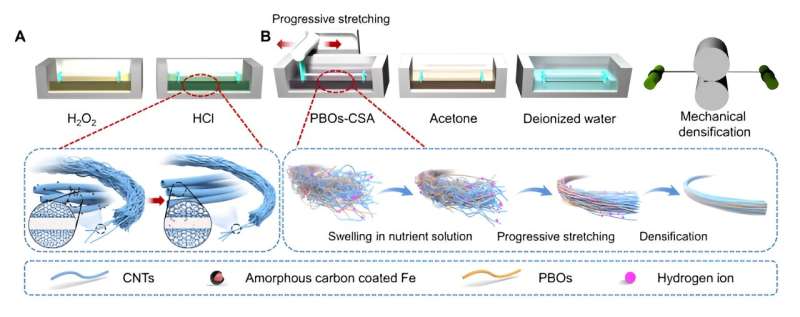

Firstly, the carbon nanotube fibers produced by floating catalyst chemical vapor deposition were purified and functionalized. Then, the fibers were subjected to progressive stretching in a chlorosulfonic acid (CSA) solution containing poly(p-phenylene-2,6-benzobisoxazole) (PBO), followed by mechanical densification. This strategy leads to improvements in interfacial interactions, nanotube alignment, and densification within the fibers, achieving a breakthrough in both quasi-static and dynamic strength.

The cross-scale ordered assembly of carbon nanotubes endows the fibers with excellent mechanical properties. The quasi-static strength of the carbon nanotube fibers reaches 8.2 GPa, and the traditional ballistic performance evaluation index, Cunniff velocity, exceeds 1100 m/s. In addition, the fibers exhibit good electrical conductivity.

To disclose the impact protection performance of the carbon nanotube fibers, a mini-split Hopkinson tension bar was employed to study the mechanical behavior of the fibers under high strain rate loading. The results indicated that as the tensile rate increased, the fibers experienced a transition from ductile to brittle failure behavior, rendering the fibers significant strain-rate-strengthening effects. When the strain rate was approximately 1,400 s–1, the dynamic strength of the fibers reached 14 GPa, surpassing all other high-performance fibers.

To investigate the dynamic response of the fibers, a laser-induced high-velocity transverse-impact testing was built under simulated ballistic impact loading. The results showed that the specific energy dissipation power of the fibers reached (8.7 ± 1.0) × 1013 m kg–1 s–1, far exceeding that of traditional ballistic fibers such as Kevlar.

These findings indicated that carbon nanotube fibers have great potential for application in impact protective engineering.

The synergistic enhancement of interfacial interactions, nanotube alignment, and densification of carbon nanotube fibers is crucial for their excellent mechanical properties. In-situ Raman testing and molecular dynamics simulations indicated that strong interactions between PBO and carbon nanotubes enhance intertube interactions and stress transfer.

Coarse-grained simulation results suggested that during progressive stretching, the addition of PBO reduces fiber porosity, increases density, and decreases stress concentration.

Under high-speed loading conditions, a higher proportion of carbon nanotubes in the fibers break, and the fiber fracture mode transitions from intertube sliding to more synchronous carbon nanotube fractures, thereby endowing the fibers with superior dynamic mechanical properties.

Carbon nanotube fibers, characterized by their extremely high dynamic strength, hold potential for applications in aerospace and impact protection. This study provides a feasible route to harness the intrinsic strength of individual carbon nanotube at the macroscale to fabricate impact-resistant fibrous materials.

More information: Xinshi Zhang et al, Carbon nanotube fibers with dynamic strength up to 14 GPa, Science (2024). DOI: 10.1126/science.adj1082

Journal information: Science

Provided by Chinese Academy of Sciences