This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

New method minimizes alignment errors in microlens array production

Double-sided microlens arrays (DSMLAs) play a crucial role in improving the performance of optical devices, supporting applications from advanced imaging systems to laser beam homogenization. However, traditional manufacturing methods often struggle with alignment errors that diminish the functionality and efficiency of these arrays.

Typically, these errors arise from the uniform thermal expansion of molds made from a single material, neglecting the complex thermal dynamics involved in precision glass molding (PGM). Such discrepancies in alignment can notably affect the optical quality and performance of DSMLAs, highlighting the need for an innovative solution to this enduring challenge in optical engineering.

Researchers from the Beijing Institute of Technology have unveiled a novel strategy that significantly reduces alignment errors in DSMLA fabrication, as detailed in a paper published in Microsystems & Nanoengineering on April 7, 2024.

Their method centers on utilizing mold assemblies composed of materials with differing thermal expansion rates, allowing for the automatic correction of alignment errors during the molding process.

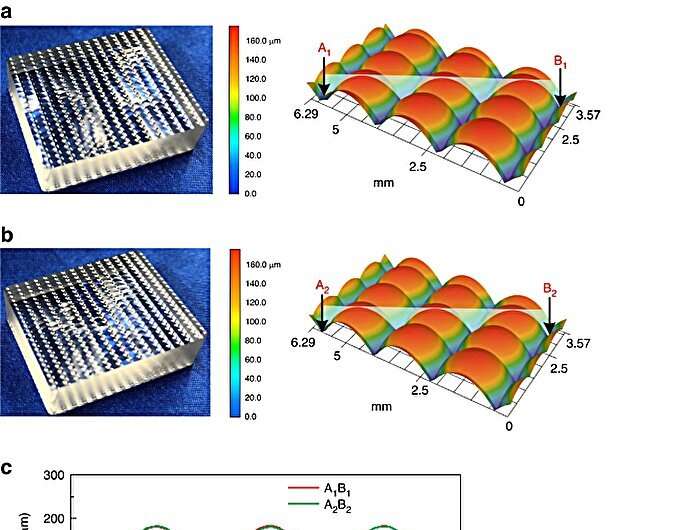

Through a detailed mathematical model, the team was able to account for the unique thermal behaviors of the selected materials, enabling precise adjustment of the gap between mold cores and sleeves. This optimization drastically reduces alignment errors, achieving unprecedented precision in DSMLAs.

Moving beyond the constraints of conventional single-material molds, which are prone to alignment issues due to uniform material expansion, this innovative approach uses materials that expand at different rates. This adjustment ensures that the mold self-corrects during heating and cooling phases, markedly improving the alignment of microlens arrays and setting a new standard in optical device manufacturing.

Tianfeng Zhou, the senior author of the study, states, "Our research not only tackles a long-standing challenge in optical manufacturing but also establishes a new benchmark for the precision and efficiency of microlens arrays. The integration of diverse materials in mold design marks a pivotal shift for the industry."

This technique marks a significant leap in optical manufacturing, offering a viable solution to one of the sector's most persistent problems. The meticulous control over alignment errors not only promises to elevate the quality of DSMLAs but also to boost the performance of optical devices dependent on these components.

More information: Zihao Zeng et al, Alignment error modeling and control of a double-sided microlens array during precision glass molding, Microsystems & Nanoengineering (2024). DOI: 10.1038/s41378-024-00668-7

Journal information: Microsystems and Nanoengineering

Provided by TranSpread