This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Simulating ejecta on titanium spacecraft surfaces under re-entry extreme environment conditions

The upper-stage helium tank of the Ariane 3 that was launched in 1985 was recovered in Uganda in 2002 after re-entry. Molten aluminum splashes were discovered on the tank, which have been identified as deposits from local fixings.

The ESA and CNES (French Government Space Agency) want to further investigate how the splashes were caused and the potential effects on titanium and stainless steel materials by recreating, for the first time, this extreme environment and re-entry scenario on the lab scale.

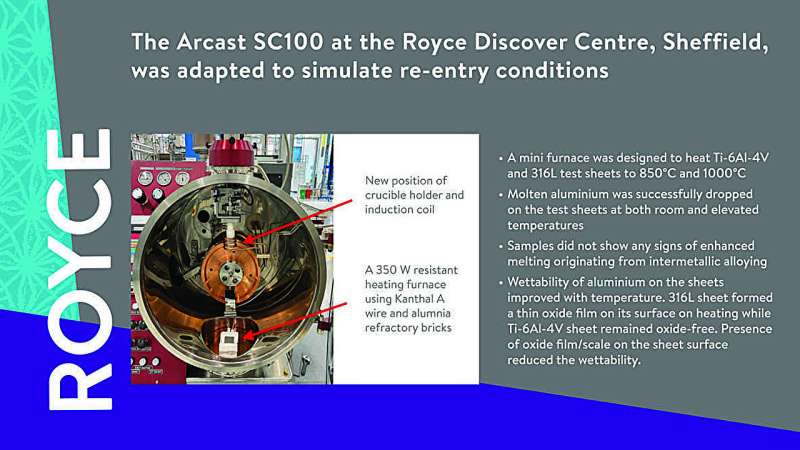

Dr. Yunus Azakli, Engineering Lead for Materials Discovery and Prototyping, adapted the Arcast SC100 at the Royce Discovery Center, Sheffield, to drop molten aluminum on to sheets of Ti-6Al-4V and 316L that had been heated by a specially designed mini furnace to recreate the Ariane 3 materials found in 2002 following its re-entry.

The conditions during atmospheric Earth re-entry of spacecraft can cause some aluminum alloy parts to melt and deposit onto other metallic components. The interaction of such ejecta with titanium components such as helium pressure tanks has, so far, not been widely researched and there is uncertainty on the surface reactions during re-entry.

This study was undertaken to determine whether such aluminum ejecta interactions could have a detrimental effect on titanium (as well as stainless steel) substrates with surface temperatures around 1,000°C in order to closely replicate Earth re-entry conditions. An Arcast melt spinning module was modified to drop controlled amounts of molten, high-purity aluminum onto Ti-6Al-4V and 316L sheets at high temperatures and room temperature under an inert atmosphere.

The new adapted melting facility at Royce provides opportunities to assess molten aluminum on high temperature substrates. This is a cost effective means of providing researchers with accurate materials to use to investigate the impact of re-entry on key spacecraft components.

Understanding the effect of the extreme conditions of re-entry will allow engineers to continue to develop more resilient and efficient materials with a view to minimizing waste and increasing sustainability.

Provided by University of Sheffield