This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Algae combined with visible light may create ink for cultured meat

A few years ago, a French daily newspaper published an article titled "Korea's Utilization of Algae as a food ingredient for the Earth." The article highlighted the ecological potential of algae, which Westerners typically find unappealing due to its soft and pulpy consistency. Algae possesses the ability to absorb atmospheric carbon dioxide and generate significantly less carbon emissions.

Consequently, the mere act of consuming algae could play a constructive role in environmental protection. Nonetheless, advancements have been made in the production of cultivated meat using algae, thus presenting a novel approach for Earth preservation. Furthermore, algae can also be utilized in the engineering of artificial organs for those who are suffering from organ failure.

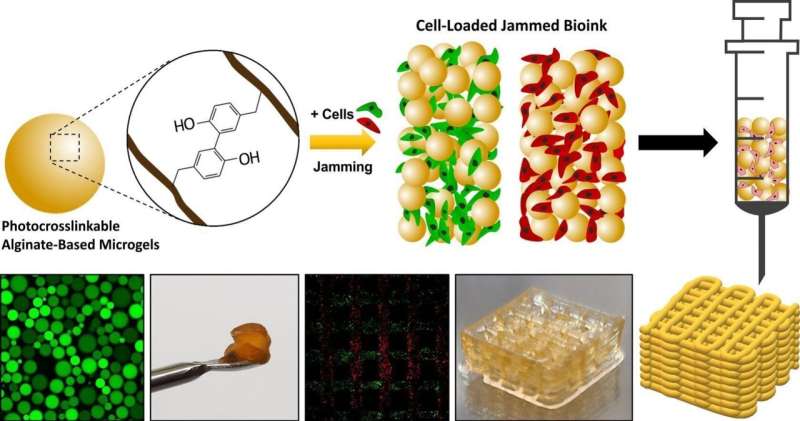

The research team led by Professor Hyung Joon Cha from the Department of Chemical Engineering and the School of Convergence Science and Technology, and Ph.D. candidate Sangmin Lee and Dr. Geunho Choi from the Department of Chemical Engineering at POSTECH have developed a bioink characterized by enhanced cell viability and printing resolution.

This accomplishment was achieved through the utilization of alginate derived from algae, a natural carbohydrate, and a harmless visible light. The research findings have been published in Carbohydrate Polymers.

3D bioprinting is a methodology employed in the fabrication of artificial organs or tissues through the use of bioinks which contain cells. This technique holds significant promise in the realms of tissue engineering and regenerative medicine while also attracting considerable attention within the foodtech sector due to its potential to produce cultivated meat, an emerging concept in future food production. Nevertheless, currently available bioinks exhibit limitations, impeding cell mobility and resulting in low cell viability and printing resolution.

To address these challenges, the research team devised a microgel utilizing a photocrosslinkable alginate. Then, they developed a 3D-printed bioink capable of facilitating free cell movement and proliferation by using this photocrosslinkable alginate microgel. This microgel bioink loaded with cells led to a 4-times increase in cell proliferation compared to conventional bioinks.

Furthermore, the microgel demonstrated reduced viscosity when subjected to external forces over a specified period, promptly recovering its initial shape even after deformation. These characteristics significantly increased the resolution and lamination capacity of the printing outcomes.

Professor Hyung Joon Cha who led the research explained, "We engineered functional tissue structures by employing a biomaterial-based bioink with exceptional and stable cell-loading capabilities for practical 3D printing. Future research and refinement of this technology are expected to propel its widespread adoption in the engineering of artificial organs and the production of cultivated meat."

More information: Sangmin Lee et al, Visible light-crosslinkable tyramine-conjugated alginate-based microgel bioink for multiple cell-laden 3D artificial organ, Carbohydrate Polymers (2023). DOI: 10.1016/j.carbpol.2023.120895

Provided by Pohang University of Science and Technology