New record: 3-D-printed optical-electronic integration

Optoelectronic integration offers a promising strategy to simultaneously obtain the merits of electrons and photons when they serve as information carriers, including high-density communication and high-speed information processing, paving the way for the next-generation integrated circuits (ICs).

The ever-increasing demand on bandwidth and information density in ICs calls for micro/nano functional devices that can be fabricated in 3-D ICs, which is desirable for their improved performance in data processing under lower consumption. In such highly integrated circuits, however, selective electrical modulation of specific micro/nanoscale optical devices, including light sources and waveguides, is a key requirement for yielding more functional and more compact integrated elements, but is hindered by the nonlinearity found in current electro-optic materials.

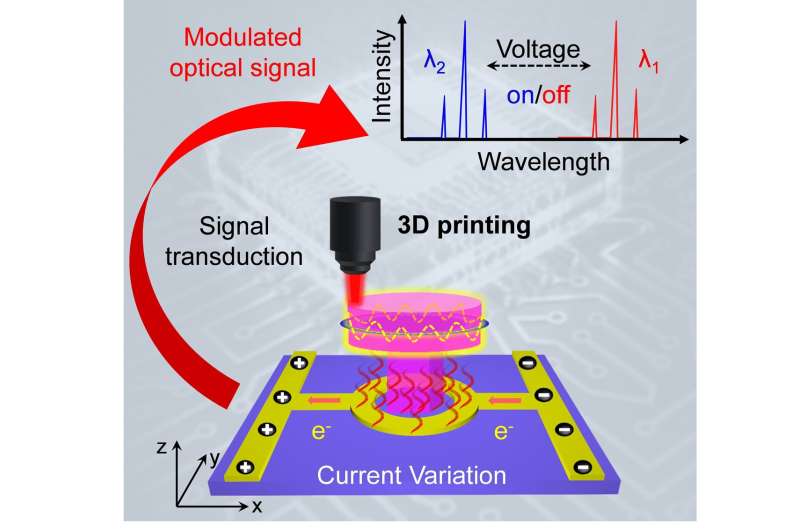

Femtosecond laser direct writing (FsLDW), as one of the 3-D printing techniques, enables the direct and addressable construction of 3-D-integrated optoelectronic devices utilizing organic compounds with two-photon polymerized features. With doping flexibility, the polymerized microstructures can be readily incorporated with organic dye molecules to produce functional devices, like coherent laser sources. Additionally, organic polymers possess excellent responsiveness to external stimuli, including temperature. Their large thermo-optic coefficient enables the realization of the electrical tuning of resonant wavelength with high efficiency when they are fabricated into microcavity structures. The incorporation of thermo-responsive polymeric microlaser with underneath electrical microheater in the 3-D fabrication manner can be used as an effective hybrid microlaser module with selective electric modulation towards optical-electronic integration.

Now, Professor Yong Sheng Zhao's group in the Institute of Chemistry, Chinese Academy of Sciences has demonstrated an in situ electrically modulated microlaser module based on 3-D-printed dye-doped polymeric microdisks, which is published in Science China Chemistry.

The thermo-optic effect of the polymer matrix enabled the tuning of lasing modes from the microdisk upon heating. The shape designability of FsLDW allows the fabrication of higher-level microstructures to manipulate light signals, including the waveguide coupled microdisks for light remote control and the coupled double-microdisk resonators for laser mode selection. The latter microstructure was further integrated with an underneath electrical microheater.

As a result, the cavity resonant wavelength can be shifted on the basis of resistance heating controlled optical length change through the thermo-optic effect of polymeric matrix material, which enables an electrical modulation of the output wavelength of the 3-D-printed microlaser module.

More information: Liu Y, Lin X, Wei C, Zhang C, Yao J, Zhao YS. 3D-printed optical-electronic integrated devices. Sci. China Chem., 2019, DOI: 10.1007/s11426-019-9503-0

Provided by Science China Press