Welding breakthrough could transform manufacturing

Scientists from Heriot-Watt University have welded glass and metal together using an ultrafast laser system, in a breakthrough for the manufacturing industry.

Various optical materials such as quartz, borosilicate glass and even sapphire were all successfully welded to metals like aluminium, titanium and stainless steel using the Heriot-Watt laser system, which provides very short, picosecond pulses of infrared light in tracks along the materials to fuse them together.

The new process could transform the manufacturing sector and have direct applications in the aerospace, defence, optical technology and even healthcare fields.

Professor Duncan Hand, director of the five-university EPSRC Centre for Innovative Manufacturing in Laser-based Production Processes based at Heriot-Watt, said: "Traditionally it has been very difficult to weld together dissimilar materials like glass and metal due to their different thermal properties—the high temperatures and highly different thermal expansions involved cause the glass to shatter.

"Being able to weld glass and metals together will be a huge step forward in manufacturing and design flexibility.

"At the moment, equipment and products that involve glass and metal are often held together by adhesives, which are messy to apply and parts can gradually creep, or move. Outgassing is also an issue—organic chemicals from the adhesive can be gradually released and can lead to reduced product lifetime.

"The process relies on the incredibly short pulses from the laser. These pulses last only a few picoseconds—a picosecond to a second is like a second compared to 30,000 years.

"The parts to be welded are placed in close contact, and the laser is focused through the optical material to provide a very small and highly intense spot at the interface between the two materials—we achieved megawatt peak power over an area just a few microns across.

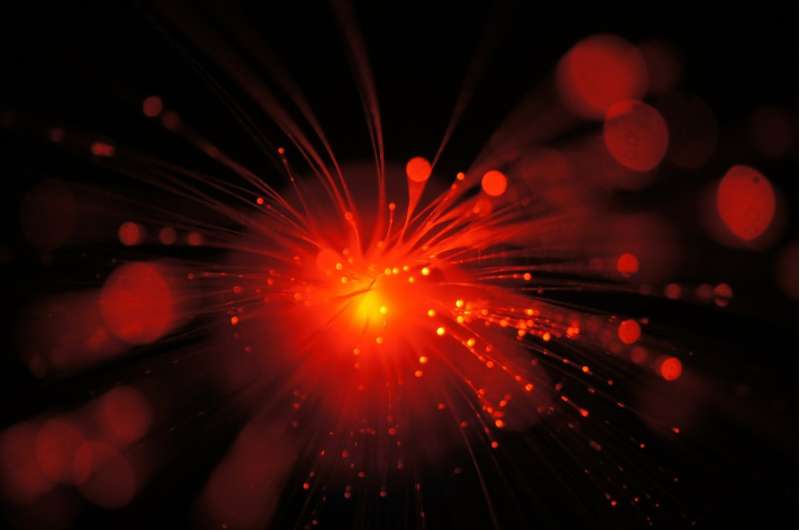

"This creates a microplasma, like a tiny ball of lightning, inside the material, surrounded by a highly-confined melt region.

"We tested the welds at -50C to 90C and the welds remained intact, so we know they are robust enough to cope with extreme conditions."

Provided by Heriot-Watt University