Electromagnetic radiation protection shields developed

The environment contains electromagnetic radiation and magnetic fields of natural and artificial origin. Even a short electromagnetic pulse is enough to knock any equipment out of operation. Candidate of Sciences (Physics and Mathematics) Aleksey Trukhanov, senior research fellow at the SUSU Nanotechnologies Research and Education Center, is studying electrolytic films to develop electromagnetic and magnetic shields capable of neutralizing this radiation.

"The issue of electromagnetic compatibility of devices is very topical today. One of the most popular methods of equipment protection used around the world is shielding—creating electromagnetic and magnetic shields. But every developer has his own design approaches and secrets, which he naturally wouldn't share. Suffice it to say that the cost of products with and without protective shielding may differ tenfold and more," says Trukhanov.

Normally, heavy elements are used as the material for shielding, as they efficiently absorb high-energy radiation. Bismuth is a heavy metal with high density and high number of shell electrons. This makes it analogous to such widely used materials as lead. However, in the ratio of the protection efficiency to mass-size parameters (as well as with consideration to the ecological aspect) bismuth is the best option.

The article, titled "Correlation of the Synthesis Conditions and Microstructure for Bi-based Electron Shields Production," has recently been published in the Journal of Alloys and Compounds. It logically follows from a previous article in the same journal, titled "Electrochemical Deposition Regimes and Critical Influence of Organic Additives on the Structure of Bi Films."

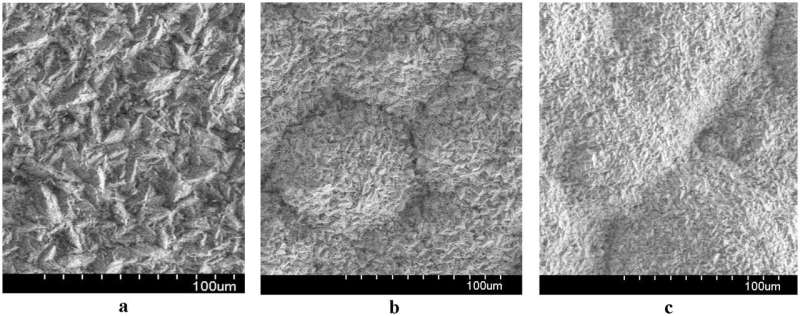

"Both articles deal with the studying of the dependency of the bismuth film microstructure and functional properties on the production process regimes and the initial electrolyte composition," explains Alexey Trukhanov. "In other words, the articles give an answer to the question of how to produce a material with identical composition but with different properties by varying different regimes in the process of electrochemical deposition. It is a well-known fact that any materials scientist holds true the following chain: composition-structure-property. And often, a material's properties are largely determined not only by the sample's chemical composition, but also by its structure."

Electrolytic films are unique from the point of view of fundamental science and application. Studying the processes of film initiation, growth mechanisms, and correlation of the structure and properties allows for a deeper understanding of the fundamental material science aspects of film technologies. However, one of the main trends of practical material science in recent decades has become the miniaturization of devices. In this context, films and coatings with pre-set or even controlled properties for functional applications turn out to be highly relevant.

"We are studying the peculiarities of the crystalline structure and microstructure (porosity, density, average size of grain) of the synthesized samples. However, it's important to understand that today, the development of science is affected by two main macro-trends: cross-sectoral cooperation and international cooperation. We're actively collaborating with our colleagues from the Head Office of Scientific Production Center for Material Sciences of the National Academy of Sciences of Belarus (Minsk, Republic of Belarus), MISIS National University of Science and Technology (Moscow), Joint Institute for Nuclear Research (Dubna)," says Aleksey Trukhanov.

As of today, electrolytic production of bismuth films has been optimized. Complex research has been performed for the phase composition and microstructure parameters of these films. It was observed that the higher the density of the film sample, the better the chances for practical application.

More information: D.I. Tishkevich et al. Electrochemical deposition regimes and critical influence of organic additives on the structure of Bi films, Journal of Alloys and Compounds (2017). DOI: 10.1016/j.jallcom.2017.11.329

D.I. Tishkevich et al. Correlation of the synthesis conditions and microstructure for Bi-based electron shields production, Journal of Alloys and Compounds (2018). DOI: 10.1016/j.jallcom.2018.03.288

Provided by South Ural State University