Researchers plumb the secrets of tissue paper

Canada's tissue manufacturers are now much closer to producing the perfect paper, thanks to new UBC research.

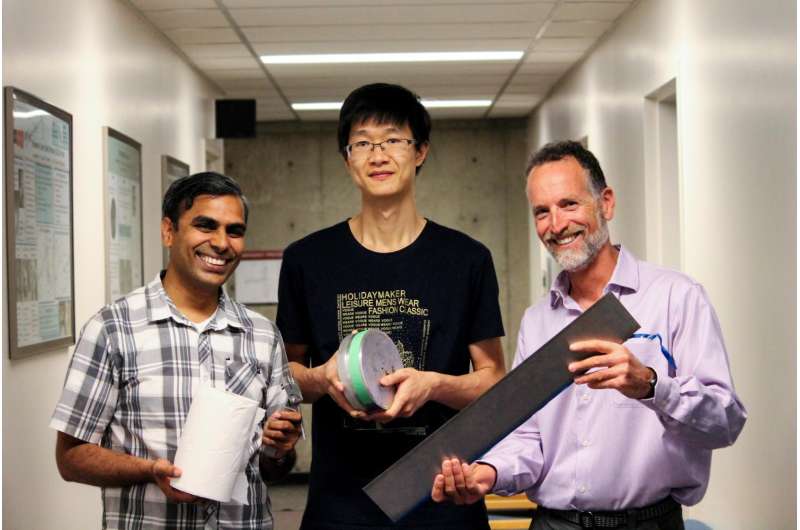

A team working with UBC mechanical engineering professors Sheldon Green and Srikanth Phani have created what is likely the first complete mathematical model of creping, the crinkling process that helps make tissue paper soft and resilient.

"The new model provides a significantly better understanding of the dynamics of the creping process, allowing manufacturers to tailor the process to a greater degree than before," said Green. "It's the most accurate model of creping to date."

During tissue manufacture, pulp is dried on a chemical-coated rotating drum until it's 95 per cent dry. It's then pushed off at very high speeds by a sharp creping blade, creating hundreds of microscopic folds that give tissue its softness, flexibility, tearing resistance and strength.

"With our model, manufacturers can better manipulate the different elements—the chemicals, the pulp, the creping blade angle, the paper speed and so on— to produce the exact product grade they want, from standard grade toilet paper to ultra-premium bathroom rolls," said Green.

"Previous simulation models were static and didn't consider the velocity and impact of the dryer," said Kui Pan, the PhD student who led the mathematical analysis.

The search for the ideal tissue paper is a top concern for the paper industry. Pan's supervisor, Srikanth Phani, believes their discovery can help paper firms in this quest.

"Canada is a strong player in the billion-dollar global market for tissue products including bathroom rolls, facial tissues, and hygiene products. This new research can contribute to the growth of that industry," added Phani.

Provided by University of British Columbia