A boost for steel: A smarter and safer way to tackle corrosion

A team from Swansea University which is developing a new 'smart release' corrosion inhibitor, for use in coated steel products, has won the Materials Science Venture Prize awarded by The Worshipful Company of Armourers and Brasiers.

Led by Professor Geraint Williams, the team, including doctorate student Patrick Dodds, is working on an alternative to hexavalent chromate, the commonly used corrosion inhibitor which is facing an EU ban in 2019. The discovery by Mr Dodds, in late 2015, of a material and manufacturing process for a smart release coating which outperforms hexavalent chromate in laboratory tests could lead to the product taking a significant slice of a multi-million pound market. The market for coiled coated steel is potentially worth £3billion per year in Europe alone.

"This is a significant breakthrough, showing a smarter and safer way of reducing corrosion. The new product is environmentally sound, economical and outperforms the market leader in laboratory tests. It illustrates that Swansea, with its close links between research and industry, remains at the heart of innovation in steel" said Professor Geraint Williams.

Corrosion inhibitors are commonly used in a wide range of sectors, including: coated steel products used to construct industrial, commercial and other buildings; aerospace and aircraft; and the car industry.

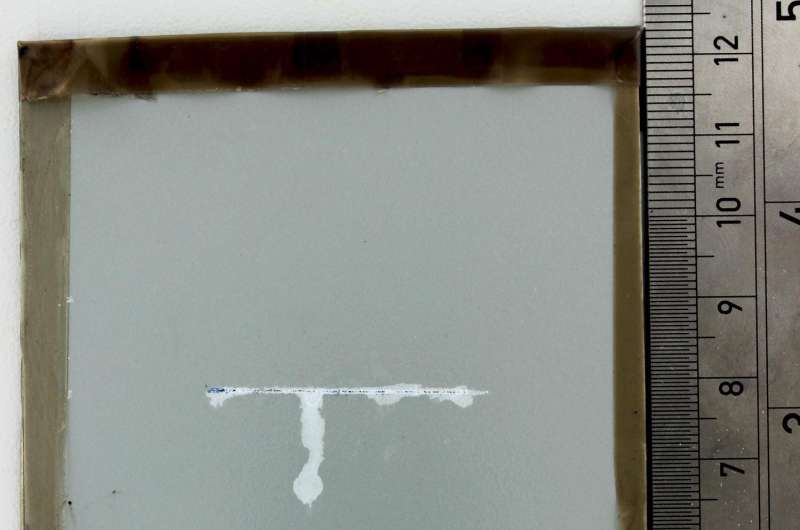

Dodds' discovery contains a stored reservoir of corrosion inhibitor. It works by channelling aggressive electrolyte anions into the coating, triggering the release of the inhibitor 'on demand', thus preventing corrosion.

"The system has been shown to prevent the onset of corrosion for over 24 hours compared to less than two hours for the current market leader," said Patrick Dodds. "We have also been able to demonstrate that the rate of corrosion can be slowed down significantly once it has started. This is by far the best result seen in 15 years of research on this topic."

"This is a significant discovery and shows how the UK is still a driving innovation force in industry," said Professor Bill Bonfield, chairman of the Armourers and Brasiers Venture Prize judging panel. "Our prize looks to encourage scientific entrepreneurship in the UK and provide funding to help discoveries like this realise their potential."

"The £25,000 prize win will be used to purchase a Jet Mill system, an essential tool for overcoming the remaining technical barriers preventing commercialisation," explained Professor Williams. "All the laboratory tests have been most encouraging and the next stage is to demonstrate technical viability and commercial scalability."

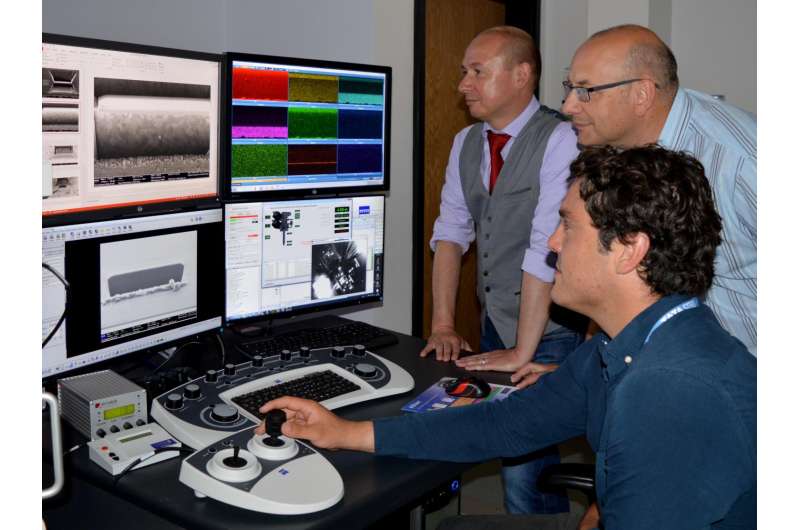

The research was carried out at Swansea University using a scanning Kelvin probe, specially built by the team, which can detect the state of the metal beneath a coating without touching it. This allowed them to test different products much more quickly, with each test taking around 24 hours, rather than 500 hours as was previously the case.

The intellectual property is owned by Swansea University, having been developed under a project co-funded by Tata Steel Colors. Swansea University has also filed a GB patent application relating to the technology. Ownership will be transferred to the spin-out company in exchange for a minority shareholding which will include a package of on-going scientific, technical and business support to ensure the company is investable.

The spin-out company will be co-located with the SPECIFIC Innovation and Knowledge Centre at Swansea University in its company incubation area. The centre's strategic partners include Tata Steel and BASF Chemicals, and it is funded by EPSRC, Innovate UK and the European Regional Development Fund through the Welsh Government.

Provided by Swansea University