Cost-saving ultrasound degassing now possible in continuous processing of aluminum melt

Having proved that ultrasound degassing of molten aluminium alloys is cleaner, greener and cheaper than current methods, a team of scientists from Brunel University London working within a European consortium has now taken the breakthrough a step further.

De-gassing the melts of aluminium alloys is a vital process otherwise the resulting solid metals end up being highly porous and often rejected for further use.

Project lead Prof Dmitry Eskin of the Brunel Centre for Advanced Solidification Technology explains: "The most common current method, argon rotary degassing, is energy intensive, involves rotating brittle parts and expensive argon gas.

"Having proved that ultrasound is cheaper, greener and just as efficient we wanted to look at achieving a continuous process that would allow us to apply degassing to much larger melt volumes and upstream from the casting mould.

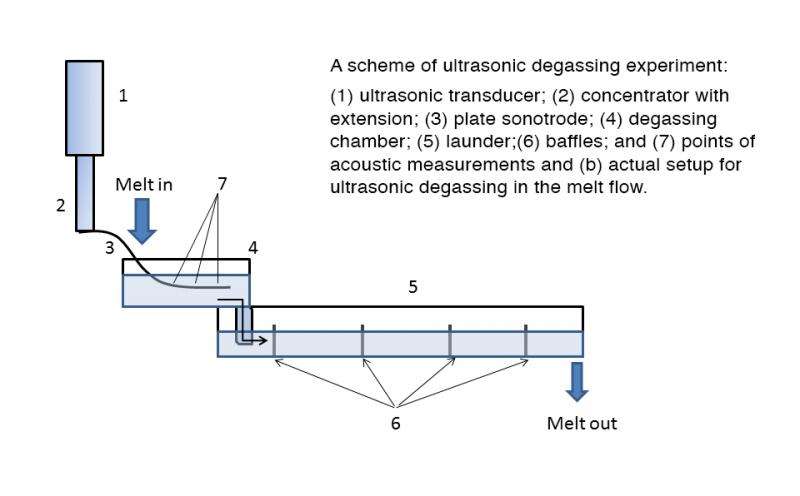

"Our experiments showed that a plate sonotrode gave a continuous degassing efficiency of at least 50 per cent in the melt flow rising to 75 per cent in batch operation. This is even more impressive than a standard cylindrical sonotrode."

Prof Eskin believes that much greater efficiencies are simply waiting to be unlocked and is seeking an industrial partner to help his team address some of the engineering challenges.

He said: "Our initial experiments were with a flat S-shaped sonotrode positioned at the bottom of the through-flow degassing chamber.

"Although the efficiency of degassing was very good, we met some engineering challenges that need to be addressed.

"For example we found that the connecting the flat sonotrode to the ultrasonic transducer and the shape and dimensions of the plate sonotrode should be optimised through engineering solutions to assure industrial-scale operation.

"In summary, to scale up from the lab to pilot studies we need an industrial engineering partner now that we know the science is sound."

Provided by Brunel University