May 15, 2015 report

Researchers demonstrate method that reduces friction between two surfaces to almost zero at macroscopic scale

(Phys.org)—A team of researchers working at Argonne National Laboratory, in Illinois, has found a way to dramatically reduce friction between two macroscopic scale surfaces—to near zero. In their paper published in the journal Science, the team describes how they accidently discovered the method and why they believe it might be useful for real world applications.

As most people are aware, friction causes energy loss and wear and tear on mechanical parts—lubricants such as oil are used to help reduce friction and to dissipate heat, but scientists would really like to find a way to prevent it from happening in the first place. In this new effort, the researchers were studying friction properties at the nanoscale, where it is more about the attractive forces between atoms, than microscopic imperfections that are present at the macroscopic scale. They were testing an idea they had, that if one flat material was coated with graphene and another with a diamond-carbon mixture, there likely would be little friction when one was slid over the other.

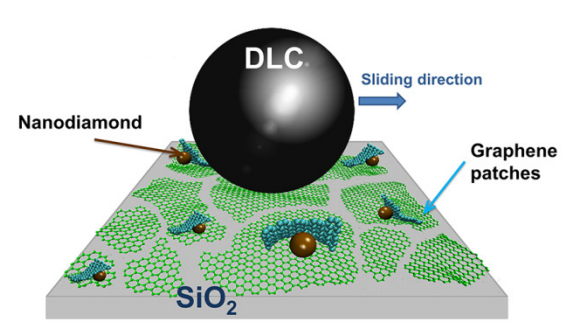

In looking at their results they noticed that sometimes they achieved a very low friction coefficient, and sometimes they did not. The difference, they found, came about when tiny diamonds came off the diamond-carbon surface which were then rolled between the two as the sliding ensued. Suspecting they had something, the team tried again, but this time after coating the surfaces, they tossed some nanodiamonds between the two, to serve as tiny ball bearings, then slid one surface over the other and found the friction between them was so low that it qualified as superlubricity.

In taking a closer look at what actually occurred during the sliding, the researchers found that as the nanodiamonds rolled under the graphene, they became coated with flakes (creating what the team calls scrolls) and that was why the friction between the two surfaces remained consistently low for the duration of the sliding. They tested the method under varying conditions, such as changing the sliding speed, the load and the temperature, and found that it worked under a most such condition, with the exception being, high humidity—water gummed up the works. The team believes the method could be used in electronic components, or perhaps in space based applications where environments are carefully controlled.

More information: Macroscale superlubricity enabled by graphene nanoscroll formation, Science, DOI: 10.1126/science.1262024

ABSTRACT

Friction and wear remain as the primary modes of mechanical energy dissipation in moving mechanical assemblies, thus it is desirable to minimize friction in a number of applications. We demonstrate that superlubricity can be realized at engineering scale when graphene is utilized in combination with nanodiamond particles and diamond-like carbon (DLC). Macroscopic superlubricity originates because graphene patches at a sliding interface wrap around nanodiamonds to form nanoscrolls with reduced contact area that slide against the DLC surface, achieving an incommensurate contact and significantly reduced coefficient of friction (~0.004). Atomistic simulations elucidate the overall mechanism and mesoscopic link bridging the nanoscale mechanics and macroscopic experimental observations.

Journal information: Science

© 2015 Phys.org