April 30, 2015 report

Researchers devise a way to grow 3 atom thick semiconducting films with wafer scale homogeneity

(Phys.org)—A team of researchers at Cornell University has developed a technique that allows for growing 3 atom thick semiconducting films on wafers, up to 10 centimeters across. In their paper published in the journal Nature, the team describes their technique and the ways it might be used to create ultra-tiny circuits. Tobin Marks and Mark Hersam of Northwestern University offer a News & Views perspective piece on the work done by the team in the same journal issue.

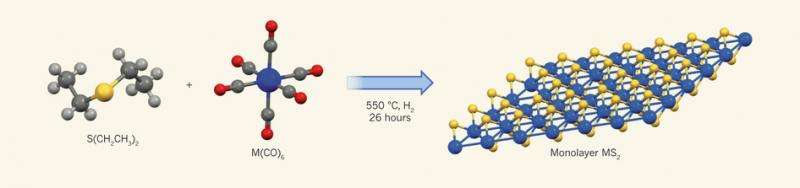

As the search continues for ways to allow for creating smaller and smaller circuits, researchers have turned to what are known as 2D materials, those that are just an atom thick—which at this point, appears to be a physical limit. Testing of such materials has proven fruitful and scientists are convinced that someday soon, they will be used in all manner of electronic gizmos. The thing holding them up right now is a means of mass producing them in sizes that are large enough to be useful while remaining homogenous across their entire surface (having spatial uniformity). In this new effort, the researchers have found success by modifying a process known as metal organic chemical vapor deposition (MOCVD) to create two types of transition-metal dichalcogenides (TMDs)—tungsten disulfide and molybdenum disulfide. One layer of the material is three atoms thick and it was created without having to resort to using sticky-tape, and unlike graphene, it is a semiconductor.

The team created their films by growing them on insulating SiO2 substrates using a metal–organic chemical vapor deposition technique. In creating 200 of the films, they found just two that failed to conduct properly—a 99 percent success rate. In testing, the films were found to be not just uniform, but comparable in performance to films created using the sticky-tape method. They note that the key to success was sourcing each of the ingredients from gasses, where every molecule had only one atom of the transition metal. Altering the gas pressure, they noted allowed for controlling the degree of concentration of the ingredients and thus the film's growth.

The researchers believe the large size of the films should allow for the creation of devices that use them, though more work will have to be done to ensure the technique will allow for growing films on other surfaces, particularly those that are flexible.

More information: High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity, Nature 520, 656–660 (30 April 2015) DOI: 10.1038/nature14417

Abstract

The large-scale growth of semiconducting thin films forms the basis of modern electronics and optoelectronics. A decrease in film thickness to the ultimate limit of the atomic, sub-nanometre length scale, a difficult limit for traditional semiconductors (such as Si and GaAs), would bring wide benefits for applications in ultrathin and flexible electronics, photovoltaics and display technology. For this, transition-metal dichalcogenides (TMDs), which can form stable three-atom-thick monolayers4, provide ideal semiconducting materials with high electrical carrier mobility, and their large-scale growth on insulating substrates would enable the batch fabrication of atomically thin high-performance transistors and photodetectors on a technologically relevant scale without film transfer. In addition, their unique electronic band structures provide novel ways of enhancing the functionalities of such devices, including the large excitonic effect, bandgap modulation, indirect-to-direct bandgap transition, piezoelectricity and valleytronics. However, the large-scale growth of monolayer TMD films with spatial homogeneity and high electrical performance remains an unsolved challenge. Here we report the preparation of high-mobility 4-inch wafer-scale films of monolayer molybdenum disulphide (MoS2) and tungsten disulphide, grown directly on insulating SiO2 substrates, with excellent spatial homogeneity over the entire films. They are grown with a newly developed, metal–organic chemical vapour deposition technique, and show high electrical performance, including an electron mobility of 30 cm2 V−1 s−1 at room temperature and 114 cm2 V−1 s−1 at 90 K for MoS2, with little dependence on position or channel length. With the use of these films we successfully demonstrate the wafer-scale batch fabrication of high-performance monolayer MoS2 field-effect transistors with a 99% device yield and the multi-level fabrication of vertically stacked transistor devices for three-dimensional circuitry. Our work is a step towards the realization of atomically thin integrated circuitry.

Journal information: Nature

© 2015 Phys.org