Growing thin films of germanium

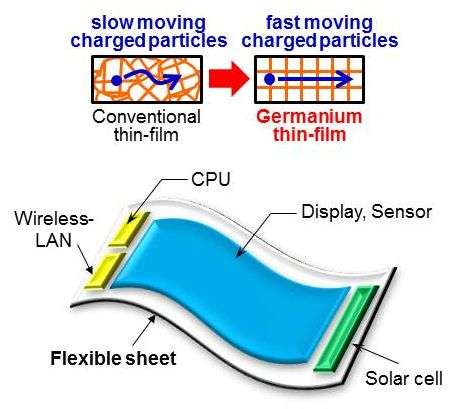

Researchers have developed a new technique to produce thin films of germanium crystals—key components for next-generation electronic devices such as advanced large-scale integrated circuits and flexible electronics, which are required for gadgets that move or bend.

Unlike conventional methods, the new approach does not require high temperatures or other crystals to act as seeds to grow the germanium crystal. And, the researchers say, the new method can be used to produce germanium films with a very large area, allowing for more potential applications.

"This is the realization of the dreams of crystal-growth researchers," says Taizoh Sadoh of Kyushu University. "This unique method will open new ways to create advanced flexible electronics."

Sadoh is an author of the paper describing the new work, which appears in the AIP Publishing journal Applied Physics Letters.

Charged particles move through germanium more readily than they do through silicon, making germanium a good material for electronics. In particular, it is a promising material for the thin-film transistors that are needed for flexible electronics. However, for use in flexible electronics, the germanium would have to be grown on malleable materials, which tend to soften at temperatures above 300° Celsius. The challenge, said Sadoh, is to grow germanium at lower temperatures.

Using gold as a catalyst, Sadoh and his colleagues were able to grow germanium crystals at a temperature of about 250° Celsius. They were also able to grow them in such a way that their crystal structure has the proper orientation and electrical properties necessary for technological applications.

More information: The paper, "Nucleation controlled gold-induced-crystallization for selective formation of Ge(100) and (111) on insulator at low-temperature (~250° C)" by Jong-Hyeok Park, Tsuneharu Suzuki, Masahi Kurosawa, Masanobu Miyao and Taizoh Sadoh appears in the journal Applied Physics Letters: dx.doi.org/10.1063/1.4819015

Journal information: Applied Physics Letters

Provided by American Institute of Physics