Hard materials: Carbon nitride for tribological application

Carbon nitride is an attractive material for its expected hardness of the hypothetical compound β-C3N4. On the other hand, amorphous carbon nitride (CNx) exhibits a low friction coefficient under certain conditions, a property that is promising for tribological application.

However, it is difficult to deposit carbon nitride on steel substrates due to adverse effects associated with carbon/nitrogen atom diffusion into the steel substrate at elevated temperatures during deposition.

Now, Toshiaki Yasui and colleagues at Toyohashi Tech show that thick layers of CNx can be coated onto steel substrate at elevated temperatures, and describe the mechanical characteristics of coating.

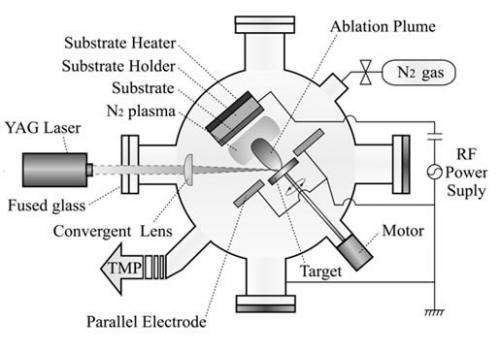

The CNx coatings were deposited on steel substrates by radio frequency plasma assisted pulsed laser deposition with substrate heating. A pulsed Nd:YAG laser (532 nm, 30 mJ) was irradiated onto high purity graphite target. RF power (13.56 MHz, 60 W) was applied to substrate to generate nitrogen plasma around it. Polished steel substrates were heated up to 673 K by a ceramic heater.

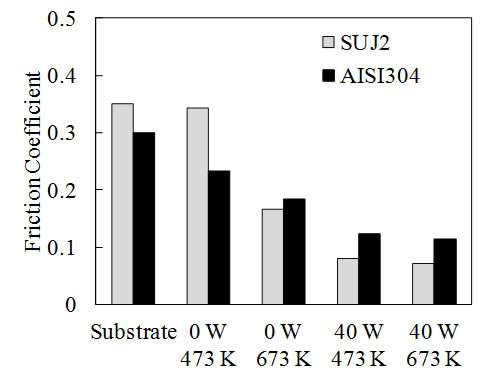

The friction coefficient of the CNx coating decreased with RF power and substrate temperature. The minimum friction coefficient of 0.072 was achieved for SUJ2 substrates by high hardness of the CNx coating.

CNx coating could find applications as tribological materials for mechanical instruments.

More information: Yasui, T. et al. Carbon nitride deposition onto steel substrate by radio frequency plasma assisted pulsed laser deposition with substrate heating, Thin Solid Films, 523, 20-24 (2012). DOI: 10.1016/j.tsf.2012.05.060

Provided by Toyohashi University of Technology