May 20, 2013 report

Company pioneering new types of material for 3-D printer 'ink'

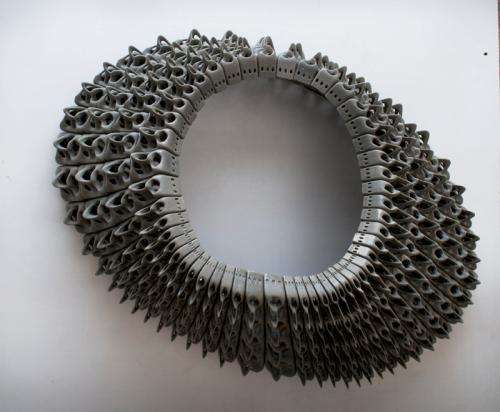

(Phys.org) —Emerging Objects, a San Francisco based fabrication studio, is pioneering the use of new kinds of material for use as an "ink" with 3-D printers. To date, their materials are based on wood, salt, paper, cement, nylon and acrylic. Launched and run by architects Ronald Rael and Virginia San Fratello, the aim of the company is to develop material for the creation of 3-D buildings, building parts, and interior accessories using natural or renewable components.

3-D printing, also known as additive manufacturing because of the nature of the process, is a relatively new science. A liquid material is applied to a base, allowed to dry, then applied again, over and over, resulting in the creation of a three-dimensional object. To date, most advancements in the field have centered around the printer—Emerging Objects is instead focusing on the material that is used as the ink.

As noted on Rael and San Fratello's website, plastic, the standard ink used as a base material for 3-D printers, is both limiting and environmentally unfriendly. Other materials, they say, allow for the creation of objects that look and feel different, and don't pollute. One example is acrylic—objects printed using it as a base are brittle and rigid, similar to glass, but also have a smooth, powdery feel. Perhaps more exciting are printed objects that look like they are made out of wood. The base material is wood pulp, but because of the 3-D layering process, the resulting materials have a natural-grain appearance.

The company points out that because their materials are made from natural local components, they cost much less than plastic. For example, they've printed objects made mostly of salt obtained from nearby San Francisco Bay. In addition, the size of the printed objects using the new materials is limited only by the size of the printer. The team is currently working on printing a room-sized object that, because it will be made mostly of salt, will look like it's made out of milk.

The objects being produced by Emerging Objects offer a glimpse of the exciting future of 3-D printing technology. At this point, it's possible to imagine giant printers one day laying down new houses or skyscrapers, or even on-demand machines in our homes that conjure almost any object we desire—much like the replicator of Star Trek fame, perhaps?

© 2013 Phys.org