Nanostructure of cellulose microfibrils in spruce wood

Scientists at Institut Laue-Langevin in Europe recently described in PNAS the first detailed structure of cellulose fibres from any higher plant.

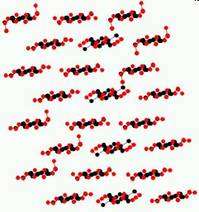

Certain algae produce highly crystalline cellulose fibres from which the structure of crystalline cellulose was deduced nearly a decade ago using neutron diffraction at the ILL. However only about half of the cellulose in fibres from wood and crop plants is crystalline: the rest is disordered, and the challenge was to find out how the crystalline and disordered parts fit together.

The results give us insights into how plants make cellulose, how the cellulose that they make defines their shape and how it provides their mechanical strength. Knowing the structure of cellulose fibres will also help us to use them in making strong, sustainable composite materials and in degrading them to make second-generation biofuels.

These experiments required wood in which the cellulose was particularly uniformly oriented, giving it a very high strength: weight ratio.

Scientists used Canadian Sitka spruce wood from a classic racing yacht’s mast. This wood is thought to have been harvested in the 1940s for aircraft construction during WWII. They also used Sitka spruce samples carefully selected from a Forestry Commission breeding trial: the best of this material was comparable with the old-growth Canadian wood.

Neutron scattering at the instrument D11 of the Institut Laue-Langevin gave the key evidence about the structure of the cellulose. Thus, the diameter of the cellulose microfibrils could be determined. As the hydrogen molecules were exchanged at the microfibril surfaces for deuterium, the D2O pushed the microfibrils apart. Penetration of D2O between the microfibrils is relevant for the enzymatic depolymerisation of the cellulose during biofuel manufacture.

More information: PNAS paper www.pnas.org/content/early/201 … /1108942108.full.pdf

Provided by Institut Laue-Langevin