New Gas Sensors Patterned with Conducting Polymer

A n improved method for depositing nanoporous, conducting polymer films on miniaturized device features has been demonstrated by researchers at the National Institute of Standards and Technology (NIST).

Described in the April 6 issue of the Journal of the American Chemical Society,* the method may be useful as a general technique for reproducibly fabricating microdevices such as sensors for detecting toxic chemicals.

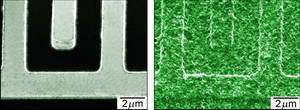

These colorized scanning electron micrographs show a portion of the NIST microheater device before (left) and after (right) application of the sponge-like polyaniline coating.

Unlike most polymers, conducting polymers have the electrical and optical properties of metals or semiconductors. These materials are of increasing interest in microelectronics because they are inexpensive, flexible and easy to synthesize.

Polyaniline is a particularly promising conducting polymer for microelectronics applications, but it is difficult to process because it doesn't dissolve in most solvents. NIST researchers have circumvented this problem by dispersing nanoscale particles of polyaniline into a mild solvent.

"The beauty of the method,” says NIST guest researcher Guofeng Li, “is that the polyaniline chain carries a natural positive charge.” Once the particles are formed, electrostatic repulsion prevents them from clumping together. Moreover, the positively charged particles then can be manipulated and patterned on complex device structures by applying an electrical field.

The process produces a sponge-like coating that efficiently captures gaseous molecules. So far NIST researchers have demonstrated that such coatings can detect the difference between methanol and water vapor. Additional tests will be needed before the polymer devices could be used for detecting toxic gases.

NIST holds patents for previous work using microheaters coated with nanostructured tin oxide films. As the microheaters cycle through a series of temperatures, changes in electrical resistance are used to detect toxic gases at part per billion levels. Ultimately, NIST researchers hope to develop inexpensive arrays of microheater sensors coated with both polymer and inorganic oxide films optimized to identify the components of gas mixtures.

*G. Li, C. Martinez, S. Semancik. Controlled electrophorectic patterning of polyaniline from a colloidal suspension. Journal of the American Chemical Society, April 6, 2005.

Source: NIST