January 19, 2007 feature

Super honeycomb shows more potential for carbon nanotubes

The hexagonal network structure makes these nanotubes look a bit like a honeycomb—or, when stretched a bit, like a hammock or fish net. In fact, the stretchiness of these 20-nm-long carbon nanotubes enables them to do what straight nanotubes find difficult: namely, transfer tensile forces and possess high ductility, or malleability.

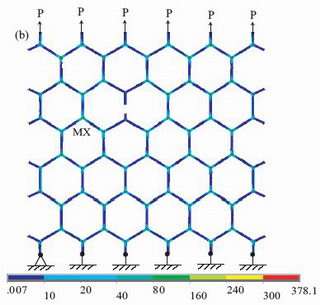

Scientists Min Wang, Xinming Qiu, and Xiong Zhang from Tsinghua University in Beijing recently investigated the mechanical properties of super honeycomb structures, which are made of periodically repeating carbon nanotube Y junctions that form hexagonal patterns. While straight nanotubes—such as those compiled in bundles or ropes—have renowned strength and elasticity, the honeycomb structure can also transfer these forces to different parts of its structure.

“The basic properties of super structures are due to their excellent structures: the hollow structure of arms and perfect honeycomb structure to combine the arms,” Zhang told PhysOrg.com. “Compared with the straight nanotube, the honeycomb structure optimizes the force-transferring.”

Although the honeycomb structure may look like a fishnet, the forces that determine the nanostructure’s properties are actually quite different from those of a macroscopic honeycomb or fishnet because of the great scale difference. For example, the scientists indicate that the van der Waals interactions and the recombination of bonds at the atomic level would affect the results when the structure is stretched.

“In our article, the shell model is used to analyze the mechanical properties of the super honeycomb structure,” Zhang said. “The method is based on the continuum theory, but the material parameter is obtained from the atomic level.”

The scientists found that, when the nano honeycomb was stretched, the structure still maintained high tensile strength. This result arises due to the honeycomb structure’s unusual tendency to become very thin (which is called having a high “Poisson’s ratio”), and gain great flexibility. The scientists found that, the more junctions, the greater strength and ability to “shift” weight to different parts of the structure.

“Because the honeycomb structure has the ability to transfer forces, the structure ensures the good distribution of stress and avoids the local stress concentration,” said Zhang. “Even when some tubes are broken from others, the whole structure can still bear the load, which embodies high ductility.”

Because the shape of a single Y junction looks like that of a carbon-carbon bond in graphite, the periodically repeating Y pattern has earned the name “super graphite.” Therefore, by rolling up a sheet of honeycomb, you get what the scientists call a “super carbon nanotube.” Using super carbon nanotubes, scientists could build high-strength, large-scale super structures with relatively short tubes that have many junctions as opposed to using longer straight tubes.

“Super carbon nanotubes are composed of the lower-order nanotubes by replacing the atomic bonds in the carbon nanotubes, which hold the superior properties of carbon nanotubes and the optimal ductility, which is due to the honeycomb structures,” Zhang explained.

The super honeycomb’s ability to transfer forces means that these structures could provide scientists with resources to improve nanoelectronics devices for computers, and also fiber-reinforced composites.

“Many nanoelectronic devices based on Y-junction carbon nanotubes have been proposed recently,” said Zhang. “Scientists [Coluci] have discussed the electronic properties of the super structures, and indicated that they have great applications as actuators and as hosts for large biomolecules. Regarding fiber-reinforced composites, just as its name implies, the mechanical properties of materials such as resin and concrete can be improved by adding some fiber components.”

Citation: Wang, Min, Qiu, Xinming, and Zhang, Xiong. “Mechanical properties of super honeycomb structures based on carbon nanotubes.” Nanotechnology. 18 (2007) 075711 (6pp).

By Lisa Zyga, Copyright 2006 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.