January 11, 2007 feature

Nature’s frugal glues provide insight for optimized adhesives

In trying to create a “glue” that would hold right up to the breaking point of the material being glued, scientists have found that such an ideal adhesive already exists—in bone, abalone shells, and spider silk, to name a few areas.

What these three natural materials have in common, scientists Paul Hansma, Patricia Turner and Rodney Ruoff found, is an optimized adhesive based on sacrificial bonds and the hidden length mechanism. The scientists foresee that these characteristics may help researchers design and fabricate optimized adhesives for nanocomposite materials, such as carbon nanotubes and graphene sheets.

“It’s important to make a composite material without compromising the material’s properties of the strong components, such as the nanotube or graphene sheet,” Hansma explained to PhysOrg.com. Optimal glue would enable these materials to retain their intrinsic properties—especially strength.

As Hansma et al. explain in their paper in Nanotechnology, optimized adhesives can hold together strong elements of materials, and yield just before these elements would break, so as not to cause the entire structure to break.

To achieve this precise strength and damage resistance, biomaterials make use of sacrificial bonds. These weak bonds form from charged side groups on biological adhesive molecules (such as polymers). With the addition of energy due to the stretching of the material, these weak bonds break—however, the process is reversible, giving the material the ability to heal itself. Human and animals bones, abalone shells, and spider silk all make use of this mechanism of sacrificial bonds and hidden length.

“Abalone shell and bone can heal themselves due to the weak bonds, such as hydrogen bonds or ionic bonds, that can reform,” Hansma explained.

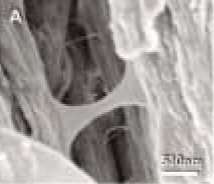

The key to obtaining a perfect amount of adhesive force is to use a precise amount of adhesive itself. Hansma et al. explain that nature acts frugally, with glue often making up as little as one percent of the entire material, by weight. Sometimes, nature even prefers voids over extra glue—which contrasts with current engineering, note the scientists, where the space between elements is often completely filled in with epoxy.

As the scientists explain, the longer the material (such as a steel bar) the lower the percentage of adhesive weight. They point out that one type of material—“ultra-high-molecular-weight polyethylene chains”—is so long that the weak interactions between the chains themselves provide enough adhesion for the structure, and no added glue is needed at all.

“Nature's adhesives tend to be charged polymers, long polypeptides with both positive and negative charged groups along the backbone,” said Hansma. “These adhesives tend to use water as an environment in which weak bonds involving those charged groups can form, break and reform. The challenge will be to simulate these reformable bonds in man-made adhesives.”

Citation: Hansma, P., Turner, P., and Ruoff, R. “Optimized adhesives for strong, lightweight, damage-resistant, nanocomposite materials: new insights from natural materials.” Nanotechnology 18 (2007) 044026 (3pp).

By Lisa Zyga, Copyright 2006 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.