On the cutting edge: Carbon nanotube cutlery

Researchers at the National Institute of Standards and Technology and the University of Colorado at Boulder have designed a carbon nanotube knife that, in theory, would work like a tight-wire cheese slicer.

In a paper presented this month at the 2006 International Mechanical Engineering Congress and Exposition, the research team announced a prototype nanoknife that could, in the future, become a tabletop tool of biology, allowing scientists to cut and study cells more precisely than they can today.

For years, biologists have wrestled with conventional diamond or glass knives, which cut frozen cell samples at a large angle, forcing the samples to bend and sometimes later crack. Because carbon nanotubes are extremely strong and slender in diameter, they make ideal materials for thinly cutting precise slivers of cells. In particular, scientists might use the nanoknife to make 3D images of cells and tissues for electron tomography, which requires samples less than 300 nanometers thick.

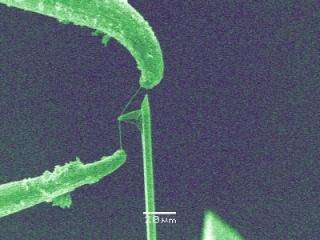

By manipulating carbon nanotubes inside scanning electron microscopes, 21st-century nanosmiths have begun crafting a suite of research tools, including nanotweezers, nanobearings and nano-oscillators. To design the nanoknife, the NIST and CU scientists welded a carbon nanotube between two electrochemically sharpened tungsten needles. In the resulting prototype, the nanotube stretches between two ends of a tungsten wire loop. The knife resembles a steel wire that cuts a block of cheese.

To begin demonstrating the feasibility of their knife design, the researchers assessed its mechanical strength in force tests, applying increasing pressure to the device. The team found that the welds were the weakest point of the nanoknife, and they are now experimenting with alternative welding techniques. The researchers plan to test the nanoknife on a block of wax later this year (cells typically are immobilized in wax for dissection and microscopy.)

Reference: G. Singh, P. Rice, R.J. McIntosh and R.L. Mahajan. Fabrication and mechanical characterization of carbon nanotube based nanoknives. Proceedings of IMECE2006, 2006 ASME International Mechanical Engineering Congress and Exposition. November 2006.

Source: National Institute of Standards and Technology