Agile new plastics change shape with heat

Researchers at MIT and the Helmholtz Association of German Research Centers have invented a class of materials so remarkable for their agility in changing shape as they react to heat, they might be described as acrobatic plastics.

The new materials, known as "triple-shape materials," can assume three different shapes, each shape depending on how much heat is applied.

This landmark achievement comes from the laboratories of chemical engineer Robert Langer of MIT and polymer chemist Andreas Lendlein of the Helmholtz Institute in Teltow, Germany.

"Triple-shape materials can switch from shape A, then to shape B, and on to shape C," Lendlein explained. "Using two, rather than just one, shape-changes offers unique opportunities for applications such as 'intelligent' stents, or 'smart' fastener systems" for use in assembling commercial products, he said.

An "intelligent stent" made of the new class of plastics could assume three different shapes to facilitate medical procedures: It would assume a handy oval shape for insertion, then a fully inflated round shape for temporary use inside a blood vessel, duct or other cylindrical organ, and lastly, a compressed cylindrical shape for easy removal.

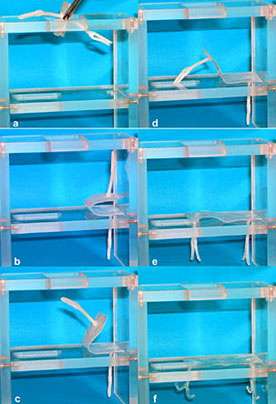

The triple-shape-shift from shape A to B to C could also have applications in industry. In factories, changeable plastic fasteners could be implanted in, or attached to, one part, then heated to extend an arm to another part. With further heating, the fastener would change shape yet again to lock itself in place. In effect, it would be an automated form of self-assembly.

Langer, an MIT Institute Professor, said, "It's like a new principle in materials, and it will be producing new opportunities. I imagine that if you had things you want to install, and then remove," the ability to change their shapes at will could be useful. "It's the first time I've seen something that will go from shape A to shape B and then shape C."

A paper on the work will appear in the Nov. 28 issue of the Proceedings of the National Academy of Sciences. Langer and Lendlein's coauthors are Ph.D. student Ingo Bellin and polymer chemist Steffen Kelch. Both work with Lendlein, who is leading the Center for Biomaterial Development in Teltow, near Berlin.

In earlier work, Lendlein and Langer invented a dual-shape class of materials, leading to what they call a "smart suture" that changes shape as needed for surgery, and they introduced a plastic that changes shape when activated by light. In November 2005 they received the World Technology Network Award for these achievements.

Source: MIT