September 21, 2006 feature

A Printer that Delivers 1,000 Pages a Minute?

Two researchers from The College of Judea and Samaria in Israel have designed an ink-jet printer head that could lead to printers capable of chugging out 1,000 pages per minute – or even more.

The innovative printer head created by engineers Moshe Einat and Nissim Einat works in a similar way as a liquid crystal display (LCD). But while an LCD emits tiny pixels of light, collectively forming the picture on your laptop or television, their print head emits pixels of ink. Their basic design is small, but it can be reproduced and the copies combined into one large printer head.

“Unlike traditional printer heads that are small and have to move back and forth across the page, our print head can be enlarged into one that is the size of a sheet of paper or larger. One can think of it as an 'ink-emitting screen',” Moshe Einat told PhysOrg.com. “This means it could print one page almost instantly, and hundreds of pages in just seconds.”

Current ink-jet printer heads work by channeling ink from a main reservoir to a series of nozzles, which are negatively pressurized to eject equal-sized ink drops. But when the number of nozzles increases, the pipe manifold connecting the reservoir to the nozzles becomes complicated and stable ink-flow conditions are harder to maintain. For example, shock waves in the ink can create “cross-talk” problems between nozzles. Another issue is the drop-ejection rate, which must be limited in order to mainstain system stability and print quality. This, in turn, stunts the print speed. The motion of standard print heads presents additional problems.

“Our design avoids these physical limitations,” said Einat.

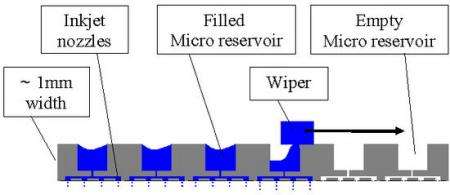

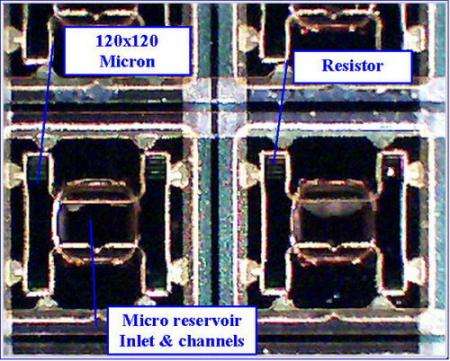

The design's building block is a micro-reservoir of ink that feeds four nozzles. The reservoir is square, one millimeter (mm) on each side, and is 0.5 mm deep. The ink enters the nozzles via capillary action (the way water naturally creeps up a plant stem, for instance). To refill, an ink-coated “wiper” slides over the top of the reservoir, depositing a layer of ink. The small amount of ink in each reservoir and the natural capillary force between the ink and the reservoir walls make pressure regulation fairly simple.

Einat and Einat combined many of these basic stand-alone segments into a 12x12 cm2 printer head matrix with a total of 57,600 nozzles. They subjected it to several tests to confirm proper ink flow within the system.

This design, which the researchers dub JeTrix, has many potential applications. Says Einat, “The future applications of JeTrix will be traditional, such as extremely high-speed printers for industry, offices, and homes. But we also anticipate brand-new, pioneering applications. One example is in-store book printing – where the book is printed instantly for the customer. This could enable small bookshops or even airport kiosks to carry a huge variety of books. There's also personalization – newspapers or journals printed with a customer's name, favorite topics, and suitable advertisements.”

He continues, “The JeTrix project is still in an early stage. The concept was proofed in a laboratory prototype, but we expect that a commercial product will be ready after two years of development, which will include additional funding and product engineering.”

For more information about this research, see the published paper in the August 15, 2006, online edition of Applied Physics Letters.

Citation: M. Einat and N. Einat, “Two-dimension full array high-speed ink-jet print head,” Applied Physics Letters 89, 073505 (2006)

By Laura Mgrdichian, Copyright 2006 PhysOrg.com