Reinforced racquets and heated wallpaper

Extremely conductive, stronger than steel and lighter than aluminum – these are only a few of the amazing properties of carbon nanotubes. An innovative method now enables the "miracle material" to be processed on an industrial scale.

Ever since they were first discovered in 1991, carbon nanotubes (CNTs) have inspired the imagination of scientists and entrepreneurs alike. They are extremely conductive, robust and lightweight. While it is meanwhile no longer difficult to manufacture nanotubes as a raw material, there are still hardly any finished products, for the material has a serious drawback: CNTs do not bind readily with other materials and stubbornly resist incorporation in the majority of production processes.

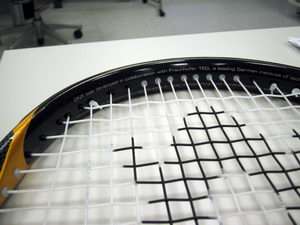

Engineers at the Fraunhofer Technology Development Group TEG in Stuttgart have at last devised a method that enables the eccentric material to be processed at low cost. Industrial mass production is possible at last. Among the first products to contain semi-finished CNT products from the TEG are the Völkl DNX tennis racquets. They have proved an outstanding success: the original plan was to manufacture 90,000 racquets, but they are selling so fast that production will probably be ramped up. "Carbon nanotubes are used to reinforce the frame at the points subjected to the greatest stress and improve the racquet's ability to absorb shocks", explains project manager Ivica Kolaric.

Kolaric and his team at the Stuttgart CNT applications laboratory are currently producing their semi-finished CNT products in paper form. The sheets look like black art paper and cost just a few euros per square meter. "We are not tied to any particular shape, though", stresses Kolaric. The CNT composite system can be mixed with many different materials and combines just as easily with plastics as with textiles. Reinforced tennis racquets are only one of many potential applications.

The researcher believes that the greatest potential for creating new products at the present time lies in harnessing the electrical properties of nanotubes to generate heat. The material is not only extremely light and robust, but can also very efficiently heat up surfaces of any size. In their various experimental applications for CNTs, the Stuttgart engineers have embedded them in kidney belts or used them to de-ice mirrors, achieving a high degree of efficiency. "The potential applications are virtually unlimited – they range from electric blankets and heatable aircraft wings that no longer ice up, through to wallpaper heating for cold walls", claims Kolaric.

Source: Fraunhofer-Gesellschaft