February 11, 2010 report

IBM develops promising contender for cheaper solar cells

(PhysOrg.com) -- Solar cells could make fossil fuels virtually redundant if they were cheaper, but their use of rare elements and complex manufacturing processes makes them expensive. Now IBM Research has developed a prototype solar cell that solves both problems, using common, cheap elements and using an inexpensive manufacturing process. Their paper is published in the Advanced Materials journal.

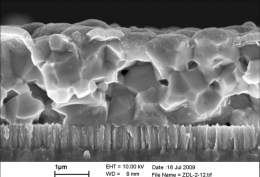

The new photovoltaic cells are known as “kesterite” cells, which are produced using a printing technology in which a solution containing nanoparticles is spin-coated onto a glass substrate. According to IBM their efficiency is close to that of established solar cells.

IBM researcher David Mitzi, who is also manager of the company’s photovoltaic science and technology department, said they wanted to reduce the cost and use more abundant elements for thin-film photovoltaic cells. The current technology uses the rare elements indium and tellurium. Indium is in particularly short supply because it is also used in the manufacture of transparent transistors and is in high demand for flat panel display systems. By contrast IBM’s kesterite cells uses the common elements tin (Sn), zinc (Zn), copper (Cu), selenium (Se), and sulfur (S).

The new solar cells are also cheaper to manufacture, using a “printing” technique that uses a hydrazine solution containing copper and tin with nanoparticles of zinc dispersed within it. The solution is then spin-coated and heat treated in the presence of selenium or sulfur vapor. This process is much cheaper than the traditional manufacturing process, which uses an expensive vacuum-based technique.

A team at the Nagaoka National College of Technology in Japan produced a thin-film kesterite cell in 2009, which had an efficiency of 6.8 per cent. IBM’s kesterite cell has increased the efficiency by 40 per cent. Mitzi said they are planning to increase the efficiency above 11 per cent, which is equal to or better than the traditional solar cells.

Solar cells contribute under 0.1 per cent of the Earth’s electricity supply at the moment, largely due to their expense and the rarity of their key elements. The IBM solar cell could change all of that. IBM will patent and license the technology and says it is open to partnerships with existing photovoltaic cell manufacturers to bring it to the market.

More information:

-- High-Efficiency Solar Cell with Earth-Abundant Liquid-Processed Absorber, Advanced Materials, DOI:10.1002/adma.200904155

-- IBM's Smarter Planet Blog

© 2010 PhysOrg.com