January 18, 2010 feature

Going Beyond Moore's Law by Using the Third Dimension

(PhysOrg.com) -- Scientists have demonstrated a new microwire fabrication technique in which microwires self-assemble themselves in a three-dimensional template made of nematic liquid crystals. Amidst concerns about Moore’s law eventually approaching a limit in two dimensions, the new fabrication method could enable researchers to continue to increase the density of transistors on integrated circuits by making use of the third dimension.

The researchers, Jean-Baptiste Fleury, David Pires, and Yves Galerne of the Institute of Physics and Chemistry of Materials of Strasbourg, in Strasbourg, France, have published their research in a recent issue of Physical Review Letters.

As the researchers explain, many different processes have been proposed in the past few years for fabricating high-quality nanowires. Generally, in order to connect nanowires to electrodes, researchers must confine them on a two-dimensional substrate and use the third dimension for manipulating the connections, often using a computer.

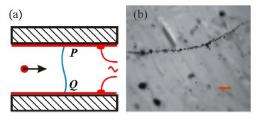

In their new study, the scientists show how to manufacture microwires that self-assemble themselves in a three-dimensional template and then connect themselves to electrodes with an accuracy of a few micrometers. First, the researchers took the two substrates to be connected, and filled the space between them with a nematic liquid crystal, which is the same substance used in many kinds of LCDs. Although the molecules in the liquid are free to move, they align themselves parallel to one another, except along threadlike (defect) lines (“nemato” in Greek means “threadlike”).

Next, the scientists created a defect line in the nematic liquid crystal that runs between electrodes in the two substrates. By rubbing the substrates in three different locations at a specific angle, the researchers produced a programmable disclination (i.e., a topological singularity or defect line). In this area, the molecules cannot orient themselves in any direction, creating a disclination that extends between the two substrates.

In addition to their ability to produce programmable disclinations, another property of nematic liquid crystals is that they attract small objects to the disclinations. This attraction occurs due to interference between the distortion from the disclination and the normal threadlike distortion from particles in the nematic liquid crystal. The interference results in a force on silica particles (which are added to the nematic liquid crystal), dragging them toward the disclination line.

Eventually, enough silica particles become trapped onto the line to form a micronecklace in which the particles are in loose contact with each other. To thoroughly join the particles together, the researchers applied a voltage difference between adjacent particles in order to polymerize monomers in the liquid crystal and eventually to stick the particles to one another. After a few hours, polymerization turned the micronecklace into a cohesive microwire.

“As far as I know, there are no other means, at the moment, able to produce microwires self-connected in 3D on designed electrodes,” Galerne told PhysOrg.com.

The researchers predict that this process can be extended to produce a large number of microwires between substrates simultaneously, which could lead to the development of large-scale three-dimensional integrated circuits. Although the microwires need to be separated from each other by a minimum distance, which presents a physical limitation, the method still has the potential to play a significant role in future electronics applications.

“The escape to the third dimension could clearly open possibilities,” Galerne said. “A simple manner could consist in connecting stacks of 2D integrated circuits. For the moment we are working on a method for producing nanowires of better quality (smoother shape, larger strength, and better conductivity).”

More information: Jean-Baptiste Fleury, David Pires, and Yves Galerne. “Self-Connected 3D Architecture of Microwires.” Physical Review Letters 103, 267801 (2009).

Copyright 2010 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.