Heat-Transfer Material Could Allow More Powerful Radar Electronics

(PhysOrg.com) -- Open any computer and you're sure to see at least one massive cooling device, complete with metal fins and a noisy fan. Today's high-power processing chips generate lots of heat -- and those chips can fry quickly without some serious cooling.

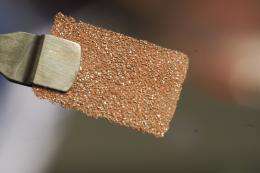

Researchers at the Georgia Tech Research Institute (GTRI) are developing a novel material for transferring heat away from ultra-high-power defense electronics. The exotic material, a composite of diamond and copper, is one of the materials under development as part of a new concept called a “Thermal Ground Plane” that aims to remove heat up to 100 times more effectively than present thermal-conducting schemes.

Such a performance leap could be vital to cooling next-generation radars, said Jason Nadler, a GTRI research engineer. Nadler is investigating ways to bring new materials and techniques to bear on the problem.

"Many areas of electronics are running up against the same issue: you just can’t move the heat away fast enough to let the devices be reliable,” Nadler said. “As we rely increasingly on very high-power devices, the methods of getting heat away from them have to become more efficient.”

Georgia Tech is working with the Raytheon Co. on a project that seeks to raise thermal conductivity capabilities to 20,000 watts per meter Kelvin (a measure of thermal-conductivity efficiency). That’s a tall order, considering that the current conductivity champion, for radar applications, is a copper material with performance of approximately 200 to 300 watts per meter Kelvin.

The three-phase, four-year project is sponsored by the Microsystems Technology Office of the Defense Advanced Research Projects Agency (DARPA).

This improved cooling capability could benefit future high-power transmit-receive (T/R) module packages. Because of their higher power, those transmit-receive modules will also have higher cooling needs that may require a Thermal Ground Plane—a sort of heat-dissipating sandwich about one millimeter thick that would be part of the T/R module’s packaging.

"A Thermal Ground Plane is basically a materials system,” Nadler explained. “The most thermally conductive natural material, pure diamond, has a conductivity of about 2,000 watts per meter Kelvin. We’re aiming for 20,000, and to do that we have to look at the problem from a materials systems standpoint.”

Nadler’s material is one of those under development to serve as the heart of the Thermal Ground Plane. The conductivity of that material would be improved with the addition of a liquid coolant able to carry heat away from the T/R module devices in the same way that sweat cools a body. A metal heat sink would help the liquid coolant dissipate the heat by condensing the vapor back to a fluid.

Using a liquid coolant takes advantage of phase changes—the conversion of matter between liquid and vapor states. The diamond-copper material would conduct heat to the liquid coolant and optimize cooling through wicking and evaporation. Then, the heat would be rejected as the vapor is re-condensed to a liquid on the side attached to the metal heat sink.

"The trick is to use evaporation, condensation and intrinsic thermal conductivity together, in series, in a continuous system,” Nadler said. “The whole device is a closed loop.”

Challenges remain, however, including some specific materials issues. To form the desired materials, diamond and copper must be integrated into a porous structure that can best transfer heat and facilitate efficient evaporation.

But diamond and copper don’t bond well, due in part to their different coefficients of thermal expansion and chemical incompatibility. Diamond doesn’t expand much when heated, while copper expands moderately. That difference leads to a thermal-expansion mismatch, which can fracture the interface between the two materials when they’re heated.

In addition, the porous internal structure of the diamond-copper material must have exactly the right size and shape to maximize its own intrinsic heat conductivity. Yet its internal structure must also be designed in ways that can help draw the liquid coolant toward the heat source to facilitate evaporation.

Nadler explained that liquid coolant flow can be maximized by fine tuning such mechanisms as the capillarity of the diamond-copper material. Capillarity refers to a given structure’s ability to draw in a substance, especially a liquid, the way a sponge absorbs water or a medical technician pulls a drop of blood up into a narrow glass tube.

To be effective, the size of a capillary structure must be precisely controlled; if it’s too large or too small, the wicking phenomenon won’t occur. The GTRI team must size the diamond-copper material’s internal structure to maximize capillarity.

"We’re finding ways to change the cellular structure of the diamond-copper material at the nanoscale and the microscale,” Nadler said. “We’re doing this by making complex open-celled structures—basically tiny foams with exactly the right properties.”

Provided by Georgia Institute of Technology