Carbon nanotubes are superior to metals for electronics

In the quest to pack ever-smaller electronic devices more densely with integrated circuits, nanotechnology researchers keep running up against some unpleasant truths: higher current density induces electromigration and thermomigration, phenomena that damage metal conductors and produce heat, which leads to premature failure of devices.

"Years ago, everyone thought that the problem of cooling for electronics could be solved," said Cemal Basaran, Ph.D., professor in the UB Department of Civil, Structural and Environmental Engineering and director of the Electronics Packaging Lab in UB's School of Engineering and Applied Sciences. "Now we know that's not true. Electronics based on metals have hit a wall. We are done with metals."

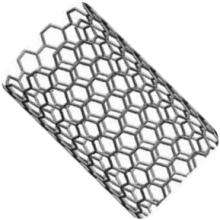

Basaran and his doctoral student Tarek Ragab have spent the past four years performing quantum mechanics calculations, which prove that in carbon nanotubes, higher current density does not lead to electromigration and thermomigration; it also produces just one percent of the heat produced by traditional metals, such as copper.

The findings demonstrate yet another tantalizing property of CNTs, he said.

According to Basaran, this essential difference between metals and carbon nanotubes lies in the way they conduct electricity.

In conventional metals, he explained, conduction causes a scattering of electrons within the lattice of the material so that, when electrons move during conduction, they bump into atoms. This creates friction and generates heat, the same way a household iron works.

He drew an analogy, using the difference between a conventional railroad train and a magnetically levitated train.

The minimal amount of friction gives carbon nanotubes a tremendous advantage over conventional metals, said Basaran. The unique properties of carbon nanotubes will allow engineers to realize a host of smaller, faster and more powerful new devices that right now cannot exist because of the limitations of conventional metals.

Much of Basaran's $1 million-plus funding at UB comes from sources like the U.S. Navy, which is interested in sophisticated electronics systems that could operate under very demanding conditions, such as the electric ship the Navy is building.

He also sounded a cautionary note, pointing out that current research and development expenditures on carbon nanotubes in the U.S. electronics industry are very small when compared to those of our Asian competitors.

Source: University at Buffalo (news : web)