Space Shuttle External Tank ET-128 Sets New Performance Standard During STS-124 Mission

When NASA's space shuttle Discovery launched from NASA's Kennedy Space Center, Fla., May 31, it was lifted from the launch pad with the help of a "new" external fuel tank, ET-128, which featured design changes made to improve performance and flight safety.

"Analysis of the tank's performance recently has been completed and the final results are in: ET-128 set a new standard in outstanding tank performance,” said John Chapman, manager of the External Tank Project Office at NASA's Marshall Space Flight Center in Huntsville, Ala.

"The tanks we're producing now are the best we've ever flown," said Chapman.

The External Tank Project Office and contractor teams’ STS-124 flight performance review began immediately following the May launch and was finalized in late June 2008.

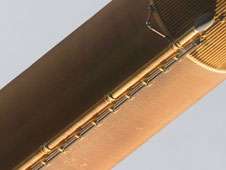

STS-124 post flight analysis of ET-128 revealed no observed foam loss from either liquid oxygen feedline brackets or hydrogen tank ice frost ramps, Chapman said. These redesigned elements flew for the first time on ET-128.

The redesign of the foam in those two areas on ET-128 and all subsequent tanks dramatically reduces the potential of liberated foam during the first 135 seconds of launch, which is the most critical time concerning foam loss.

"I'm very proud of the NASA and contractor teams for their hard work and dedication that have brought us to this point in producing a safer space shuttle external tank,” said Chapman. ET-128 is the first tank to fly with all Return to Flight improvements incorporated during production instead of being added after manufacturing was complete.

Lockheed Martin Space Systems workers have built and assembled space shuttle external tanks at NASA's Michoud Assembly in New Orleans for more than 30 years. Chapman commended the workers for their commitment to continue building quality tanks and delivering them on schedule, despite hardships they face in the continuing aftermath of hurricanes Katrina and Rita in 2005.

"These workers remain loyal and committed to building and delivering on time the 10 remaining space shuttle external tanks, even as NASA prepares for shuttle flyout in 2010," said Chapman. The agency is gearing up for the transition from shuttle to the Constellation Program, which is responsible for development of NASA’s next generation of crew exploration and launch vehicles and related systems and technologies for exploration of the moon, Mars and destinations beyond.

ET-127, the external tank for the next shuttle mission, STS-125, departed Michoud July 10, headed to the Kennedy Center, where it will be mated to space shuttle Atlantis and prepared for a scheduled Oct. 8 launch on a servicing mission to the Hubble Space Telescope. ET-129, the next tank, is scheduled for delivery to NASA later this summer and will fly on space shuttle Endeavour on the STS-126 mission to the International Space Station. Launch is scheduled Nov. 10. Endeavour also will serve as a backup rescue mission for Atlantis, if needed.

At 153.8 feet long and 27.6 feet in diameter, the external tank is the largest and, when loaded, the heaviest element of the space shuttle. It consists of three major components, the liquid oxygen tank, an unpressurized intertank that contains most of the electrical components and the liquid hydrogen tank. The giant, rust-colored structure is the "gas tank" for the orbiter and contains the propellants used by the space shuttle main engines. The tank also is the "backbone" of the shuttle during launch, providing structural support for attachment with the solid rocket boosters and orbiter. It is the only component of the space shuttle that is not reused. Approximately 8.5 minutes into the flight, with its propellant used, the tank is jettisoned and falls in a preplanned trajectory with the majority of it disintegrating in the atmosphere and the remainder falling into the ocean.

NASA continues to improve the space shuttle external tank, which began with the first Return to Flight Mission, STS-114, in July 2005. Numerous modifications have been made to reduce the amount of foam used on the tank. For a complete list of tank improvements, visit:

www.nasa.gov/centers/marshall/ … ound/factsheets.html

Source: NASA / PhysOrg.com