Feeling the Heat: Berkeley Researchers Make Thermoelectric Breakthrough in Silicon Nanowires

Energy now lost as heat during the production of electricity could be harnessed through the use of silicon nanowires synthesized via a technique developed by researchers with the U.S. Department of Energy’s Lawrence Berkeley National Laboratory and the University of California at Berkeley. The far-ranging potential applications of this technology include DOE’s hydrogen fuel cell-powered “Freedom CAR,” and personal power-jackets that could use heat from the human body to recharge cell-phones and other electronic devices.

“This is the first demonstration of high performance thermoelectric capability in silicon, an abundant semiconductor for which there already exists a multibillion dollar infrastructure for low-cost and high-yield processing and packaging,” said Arun Majumdar, a mechanical engineer and materials scientist with joint appointments at Berkeley Lab and UC Berkeley, who was one of the principal investigators behind this research.

“We’ve shown that it’s possible to achieve a large enhancement of thermoelectric energy efficiency at room temperature in rough silicon nanowires that have been processed by wafer-scale electrochemical synthesis,” said chemist Peidong Yang, the other principal investigator behind this research, who also holds a joint Berkeley Lab and UC Berkeley appointment.

Majumdar, who was recently appointed director of Berkeley Lab's Environmental Energy Technologies Division (EETD) and is a member of the Materials Sciences Division, is an expert on energy conversion and nanoscale science and engineering. Yang is a leading nanoscience authority with Berkeley Lab's Materials Sciences Division and with the UC Berkeley Chemistry Department.

Majumdar and Yang are the co-authors of a paper appearing in the January 10, 2008 edition of the journal Nature, entitled “Enhanced Thermoelectric Performance of Rough Silicon Nanowires.” Also co-authoring this paper were Allon Hochbaum, Renkun Chen, Raul Diaz Delgado, Wenjie Liang, Erik Garnett and Mark Najarian.

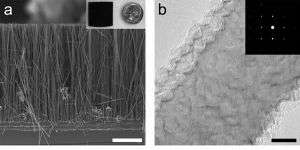

The Nature paper describes a unique “electroless etching” method by which arrays of silicon nanowires are synthesized in an aqueous solution on the surfaces of wafers that can measure dozens of square inches in area. The technique involves the galvanic displacement of silicon through the reduction of silver ions on a wafer’s surface. Unlike other synthesis techniques, which yield smooth-surfaced nanowires, this electroless etching method produces arrays of vertically aligned silicon nanowires that feature exceptionally rough surfaces. The roughness is believed to be critical to the surprisingly high thermoelectric efficiency of the silicon nanowires.

“The rough surfaces are definitely playing a role in reducing the thermal conductivity of the silicon nanowires by a hundredfold, but at this time we don’t fully understand the physics,” said Majumdar. “While we cannot say exactly why it works, we can say that the technique does work.”

Nearly all of the world’s electrical power, approximately 10 trillion Watts, is generated by heat engines, giant gas or steam-powered turbines that convert heat to mechanical energy, which is then converted to electricity. Much of this heat, however, is not converted but is instead released into the environment, approximately 15 trillion Watts. If even a small fraction of this lost heat could be converted to electricity, its impact on the energy situation would be enormous.

“Thermoelectric materials, which have the ability to convert heat into electricity, potentially could be used to capture much of the low-grade waste heat now being lost and convert it into electricity,” said Majumdar. “This would result in massive savings on fuel and carbon dioxide emissions. The same devices can also be used as refrigerators and air conditioners, and because these devices can be miniaturized, it could make heating and cooling much more localized and efficient.”

However the on-going challenge for scientists and engineers has been to make thermoelectric materials that are efficient enough to be practical. The goal is a value of 1.0 or more for a performance measurement called the “thermoelectric figure of merit” or ZT, which combines the electric and thermal conductivities of a material with its capacity to generate electricity from heat. Because these parameters are generally interdependent, attaining this goal has proven extremely difficult.

In recent years, ZT values of one or more have been achieved in thin films and nanostructures made from the semiconductor bismuth telluride and its alloys, but such materials are expensive, difficult to work with, and do not lend themselves to large-scale energy conversions.

“Bulk silicon is a poor thermoelectric material at room temperature, but by substantially reducing the thermal conductivity of our silicon nanowires without significantly reducing electrical conductivity, we have obtained ZT values of 0.60 at room temperatures in wires that were approximately 50 nanometers in diameter,” said Yang. “By reducing the diameter of the wires in combination with optimized doping and roughness control, we should be able to obtain ZT values of 1.0 or higher at room temperature.”

The ability to dip a wafer into solution and grow on its surface a forest of vertically aligned nanowires that are consistent in size opens the door to the creation of thermoelectric modules which could be used in a wide variety of situations. For example, such modules could convert the heat from automotive exhaust into supplemental power for a Freedom CAR-type vehicle, or provide the electricity a conventional vehicle needs to run its radio, air conditioner, power windows, etc.

When scaled up, thermoelectric modules could eventually be used in co-generating power with gas or steam turbines.

“You can siphon electrical power from just about any situation in which heat is being given off, heat that is currently being wasted,” said Majumdar. “For example, if it is cold outside and you are wearing a jacket made of material embedded with thermoelectric modules, you could recharge mobile electronic devices off the heat of your body. In fact, thermoelectric generators have already been used to convert body heat to power wrist watches.”

The Berkeley Lab researchers will be studying the physics behind this phenomenon to better understand and possibly manipulate it for even further improvements. They will also concentrate on the design and fabrication of thermoelectric modules based on silicon nanowire arrays. Berkeley Lab’s Technology Transfer Department is now seeking industrial partners to further develop and commercialize this technology.

Source: Berkeley Lab