Giving research a boost with cheaper biochips

An EPFL invention has drastically reduced the cost of producing biochips, which are used to measure glucose and drug levels in the blood and to detect biomolecules and cellular signals. This development could make it possible to carry out analyses that are currently considered too expensive, and thus boost many areas of research.

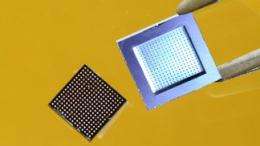

Biochips, used to diagnose genetic diseases, detect tumor markers and measure substances in the blood such as glucose, drugs or doping agents, have become widespread in the medical world over the past 20 years. Scientists in EPFL’s Laboratory of Life Sciences Electronics (CLSE) have recently completely re-engineered the design of these semiconductor biochips, coming up with a way to make them re-usable. This in turn reduces their cost by a factor of ten, which otherwise would correspond to hundreds of francs a piece. The invention was recently described in an article and an interview in the scientific journal Electronics Letters.

“The advance that we are proposing could seriously boost research in several fields,” says CLSE director Carlotta Guiducci. “Many projects, such as those looking at new ways to analyze various molecules, thus become possible, even though right now they’re difficult to carry out because experimentation using CMOS biochips is simply too expensive.”

In the core of the biochip, the risk of contact between samples containing the material to be tested – DNA, molecules, neurons or cells – and the electronics has up to now obliged users to throw them away after a single use. “The electronics aren’t compatible with the liquid environment of the sample; they can be easily damaged and the reliability of the analysis results can be compromised,” explains Yuksel Temiz, a PhD student in CLSE. “This limits their usefulness and has prevented large scale commercialization.”

To solve this problem, the EPFL scientists looked at how they could separate the liquids that needed to be analyzed from the electronic circuits. In the Center for Micronanotechnologies (CMi) cleanrooms, they developed a procedure to manufacture a component that is placed on top of the electronics, like a kind of cap. The sample of biological material, placed in the cap, never enters into contact with the circuits. Its electrical impulses are transmitted to the circuit by an array of electrodes passing through the silicon layer of the cap.

Once the analysis is done, the cap is thrown away. The caps are easy to manufacture in large quantities in cleanrooms, can be customized for the needs of each laboratory, and are very cheap – only two francs each. And because the circuits have been protected from the liquid sample, they can be re-used several times. Researchers hope to be able to use a circuit at least ten times instead of just once. This will also allow more extended measurements and thus longer and more complete analyses.

More information: Electronics Letters, "Semiconductors in Personalised Medicine"Electronics Letters, interview with Carlotta Guiducci

Provided by Ecole Polytechnique Federale de Lausanne