April 11, 2011 report

Researchers develop process to make cotton both water repellent and UV resistant

(PhysOrg.com) -- Researchers at Northeast Normal University in China, have come up with a three-step process that when applied to cotton material results in a fabric that is both waterproof and very highly UV resistant.

In a recent paper published in ACS Applied Materials & Interfaces, Lingling Wang and his associates describe a method of using zinc oxide nanorods and zinc oxide crystallites to create a coating that bonds to cotton fiber resulting in a material that its creators hope will help meet the needs of a world that wants multi-functional clothes; in this case, clothes that are "green" (don't need cleaning) and help protect the wearer’s skin from harmful ultraviolet radiation.

The process, using off the shelf materials, including the cotton material, was begun by soaking a piece of cotton cloth in ZnO nano-crystals for 12 hours, then putting it in a Teflon autoclave (high pressure steamer) that was saturated in a zinc acetate hydrate solution for 48 hours at 95° C. This first step resulted in the dissolution and then re-crystallization of the ZnO nano-crystals which gave it a ZnO seed layer. Afterwards, the material was allowed to dry for ten minutes.

The next step was to place the seeded cotton back into the autoclave, this time in an aqueous solution of zinc nitrate hydrate and hexamethylenediamine (HMT) for 5 hours at 95° C. This step gives the material its water proofing abilities. Afterwards it’s rinsed and allowed to dry again.

The final step was to dip the material alternately in polyethylenimine (PEI) and silicate solutions creating a PEI/silica layer (shell).

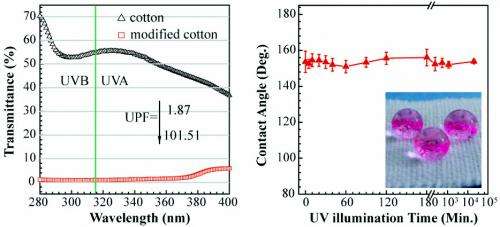

The result is a material that is not only waterproof but is able to block out UV radiation from the sun to such an extent that it would rate a Ultraviolet Protection Factor (UPF) of 101.15 if the chart went that high. The rating is in effect, double the highest possible rating on the normal chart, and considerably higher than consumers are accustomed to seeing on suntan lotion bottles.

Though testing has not been done to see how the new process will hold up under real world conditions, the knowledge gained from the success of this procedure will no doubt advance the science of developing new clothes that will provide far more benefits to us all than simply covering our bodies.

More information:

Lingling Wang et al., Superhydrophobic and Ultraviolet-Blocking Cotton Textiles, ACS Appl. Mater. Interfaces, Article ASAP. DOI: 10.1021/am200083z

via Discovery

© 2010 PhysOrg.com