This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Unraveling the impact of edge cracks on superconducting REBCO tapes: A leap in material durability and efficiency

In the realm of superconductivity, the durability and efficiency of materials like REBCO (Rare Earth Barium Copper Oxide) tapes are crucial for application in various high-tech fields. However, these materials face challenges, particularly when it comes to maintaining their superconducting properties under stress.

A recent study delves into the intricate relationship between mechanical stress and the superconducting capabilities of REBCO tapes, offering new insights that could pave the way for more robust and reliable superconducting materials.

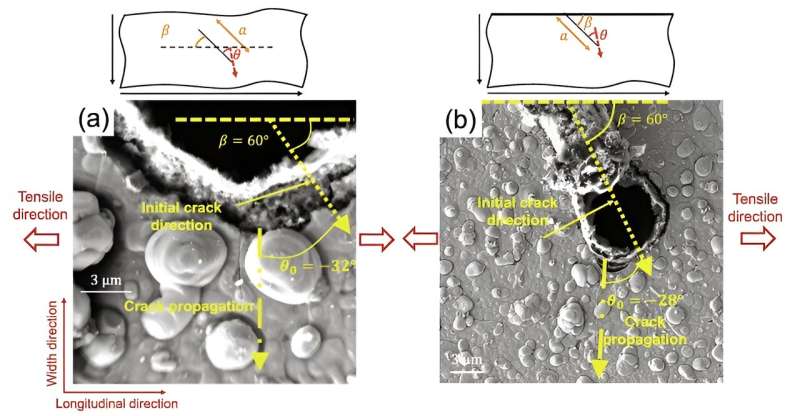

At the heart of this study is examining edge cracks caused by the slitting process in REBCO tapes when subjected to tensile stress. These tapes, known for their high critical current capacity, are essential in many superconducting applications, from medical imaging equipment to particle accelerators. It was widely believed that even minor edge cracks could propagate and cause premature degradation of REBCO tapes when subjected to stress, raising concerns about the longevity and reliability of these materials in practical applications.

The research team, led by scientists from Tsinghua University, the University of Houston, and the Chinese Academy of Sciences, employing advanced microscopic and computational techniques, meticulously analyzed how these edge cracks impact the tapes' ability to carry supercurrent without resistance.

The team examined commercial REBCO tapes manufactured by different processes and found that when the stress intensity factor at the crack tip is below a certain threshold (KIC = 2.3 MPa√m), edge cracks do not propagate, concluding that these cracks will not cause premature degradation.

One of the key takeaways from the research is a model using multiple edge crack properties to evaluate stress intensity factors. This model is particularly valuable for manufacturers, as it suggests that by controlling these factors, it might be possible to enhance the resilience of REBCO tapes against mechanical stress.

The research is published in the Superconductivity journal.

The implications of this study extend beyond the confines of the laboratory. In real-world applications, where superconducting tapes must often endure various forms of stress and strain, understanding the impact of physical imperfections becomes paramount. This research not only sheds light on the edge crack behavior of REBCO tapes but also provides guidance for the slitting process and opens up new avenues for creating more durable and efficient superconducting materials, pushing the boundaries of what's possible in the world of superconductivity.

More information: Zhirong Yang et al, Effect of edge cracks on critical current degradation in REBCO tapes under tensile stress, Superconductivity (2022). DOI: 10.1016/j.supcon.2022.100007

Provided by Shanghai Jiao Tong University Journal Center